-

×

New Holland TS125A, TS130A, TS135A Tractor Service Manual

$42.00

New Holland TS125A, TS130A, TS135A Tractor Service Manual

$42.00 -

×

John Deere 2243 Mower Repair Technical Manual (TM1473)

$32.00

John Deere 2243 Mower Repair Technical Manual (TM1473)

$32.00 -

×

New Holland T3.50F, T3.55F, T3.65F, T3.75F Tractor Service Manual

$34.00

New Holland T3.50F, T3.55F, T3.65F, T3.75F Tractor Service Manual

$34.00 -

×

New Holland T1010, T1030, T1110 Tractor Service Manual

$34.00

New Holland T1010, T1030, T1110 Tractor Service Manual

$34.00 -

×

New Holland TL70A, TL80A, TL90A, TL100A Tractor Service Manual

$36.00

New Holland TL70A, TL80A, TL90A, TL100A Tractor Service Manual

$36.00 -

×

John Deere GX70, GX75, GX85, SX85, GX95, SRX75, SRX95 Mowers Technical Manual

$30.00

John Deere GX70, GX75, GX85, SX85, GX95, SRX75, SRX95 Mowers Technical Manual

$30.00

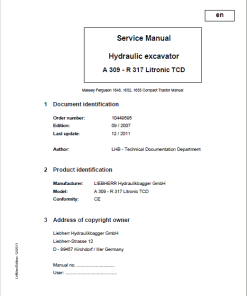

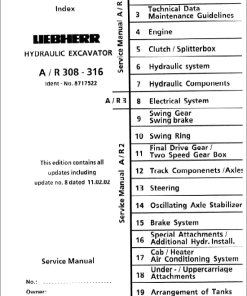

Liebherr R926, R936, R946, R950 Tier 4F Hydraulic Excavator Service Manual

$35.00

Models Covered: R 926 (from serial no. 40625), R 936 (from serial no. 40312), R 946 (from serial no. 40137), R 950 (from serial no. 42213), R 926 Compact (from serial no. 40625), R 936 Compact (from serial no. 45440), R 950 Tunnel (from serial no. 37539), R 950 Demolition (from serial no. 43111)

Language: English

Publication Number: 11692893

Format: PDF

Publication Date: January 2018

The comprehensive Liebherr R926, R936, R946, R950 Tier 4F Excavator Service Manual spans 2628 pages, while the Operator’s Manual offers detailed guidance across 324 pages.

Liebherr R926, R936, R946, R950 Tier 4F Hydraulic Excavator Service Manual

Product Overview

The Liebherr Tier 4F Hydraulic Excavator Service Manual is a comprehensive guide designed to provide detailed technical information and guidance for service and maintenance. It covers multiple models, including:

- R 926 from serial no. 40625

- R 936 from serial no. 40312

- R 946 from serial no. 40137

- R 950 from serial no. 42213

- R 926 Compact from serial no. 40625

- R 936 Compact from serial no. 45440

- R 950 Tunnel from serial no. 37539

- R 950 Demolition from serial no. 43111

Language: English

Publication: 11692893

Format: PDF

Publication Date: January 2018

This manual consists of 2628 pages for the service manual and 324 pages for the operator’s manual, offering an exhaustive resource for operators and technicians.

Key Features

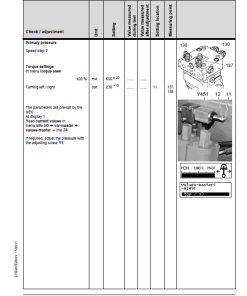

- Extensive technical data and design specifics

- Clear instructions for operation and machine adjustments

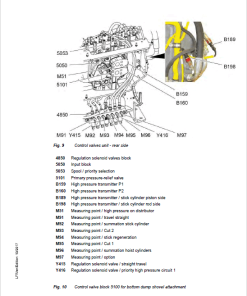

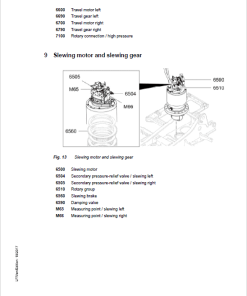

- Detailed drawings and functional schematics

- Comprehensive views of units and assemblies

Benefits

- Ensures precise maintenance and troubleshooting

- Enhances understanding of complex hydraulic systems

- Facilitates efficient and safe operation of machinery

Usage Recommendations

- Ideal for technicians servicing Liebherr excavators

- Useful for training new operators in handling hydraulic systems

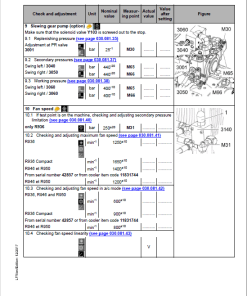

- Recommended for mechanical adjustments and settings calibration

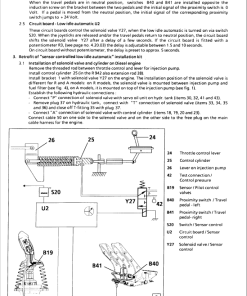

Contents of the Service Manual

- Introduction

- Technical Data

- Maintenance

- Drive Group

- Cooling System

- Working Hydraulics

- Hydraulic Components

- Steering System

- Brake System

- Electrical System

- Transmission / Travel Gearbox

- Axles / Drive

- Steel Components – Basic Machine

- Working Attachment

- Operatoru2019s Cab, Heating and Air Conditioning

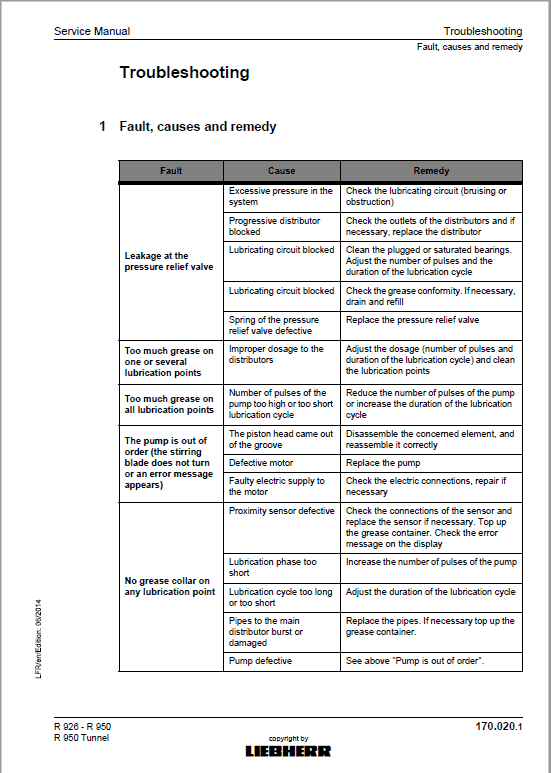

- Lubrication System

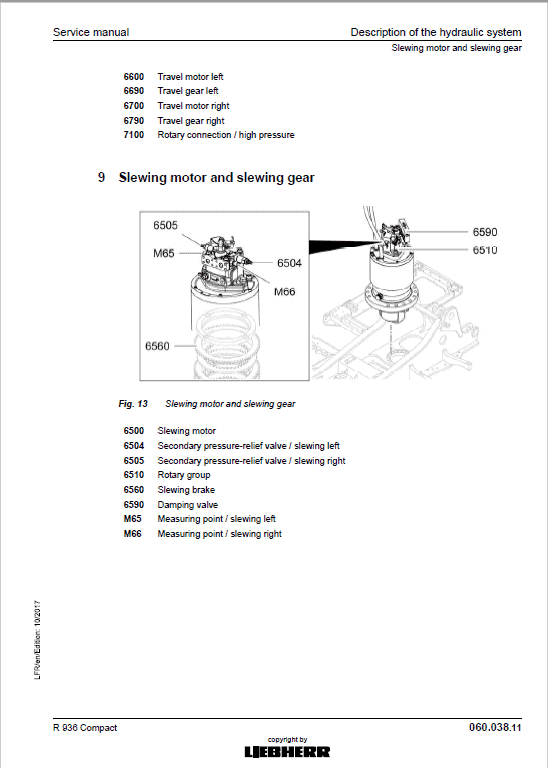

- Slewing Gearbox and Slewing Ring

- Equipment / Options

- Diagnosis

Manual Extract: Installing the New Chain

- Pass the chain under the side frame while pulling it back with a machine.

- Pull the chain until two or three links protrude from the middle of the sprocket.

- Lower the machine onto the unrolled chain.

- Jack up the rear of the chain with a lifting accessory to engage the links with the sprocket teeth.

- Position a wooden wedge against the sprocket wheel to retain the links.

- Using a machine or steel cable attached to the working attachment, lift and pull”, “

Only logged in customers who have purchased this product may leave a review.

Related products

$35.00

$35.00

$36.00

Reviews

There are no reviews yet.