Takeuchi TB290 Compact Excavator Service Manual

$34.00

Service Repair Manual: Comprehensive 518-page guide covering all service and repair needs for the Takeuchi TB290.

Operating Manual: Detailed 259-page manual providing operational instructions for optimal use of the Takeuchi TB290.

Applicable for all serial numbers (S/N).

Takeuchi TB290 Compact Excavator Service Manual

Product Overview

The Takeuchi TB290 Compact Excavator Service Manual is an essential guide for the operation, servicing, repair, and maintenance of the Takeuchi TB290 excavator. This comprehensive manual provides detailed instructions and safety guidelines to ensure smooth functioning and longevity of the machine.

Manual Details:

– Excavator Model: TB290

– Format: PDF

– Language: English

– Page Count: Service Manual – 518 pages; Operating Manual – 259 pages

– Applicable to all relevant serial numbers

Key Features

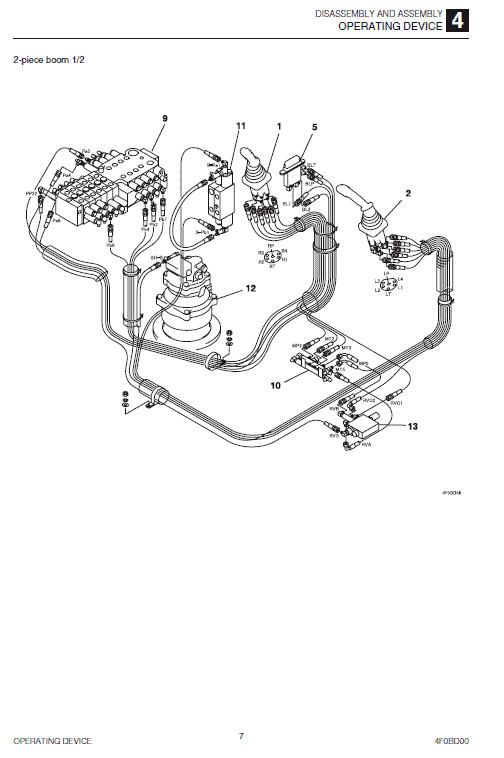

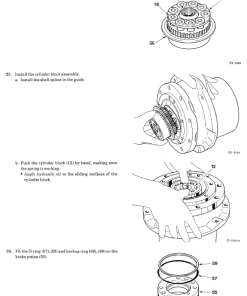

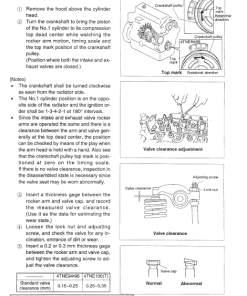

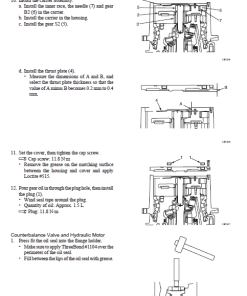

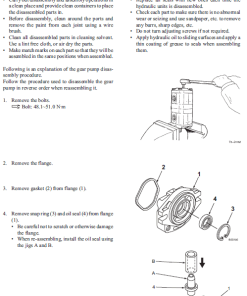

- Detailed explanations for disassembly and reassembly of the machine

- Complete check and maintenance procedures documented

- Included maintenance reference values and troubleshooting tips

- Outline specifications and safety instructions

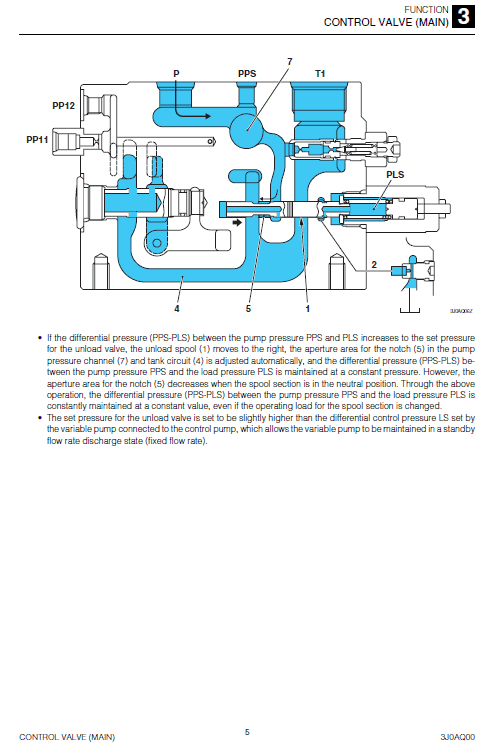

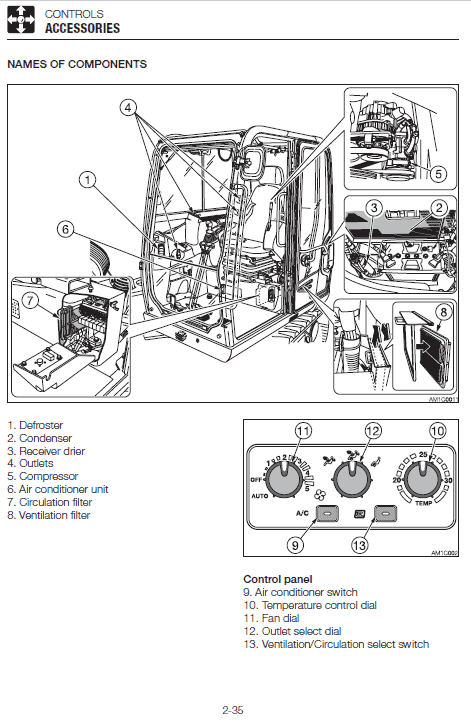

- Easy-to-follow diagrams and procedural illustrations

Benefits

- Enhance maintenance skills through comprehensive guidance

- Improve machine efficiency and operational safety

- Ensure proper documentation is provided when transferring ownership

- Access precise troubleshooting solutions to common issues

Usage Recommendations

- Store the manual near the machine for easy reference.

- Use the manual as a regular reference for service activities.

- Conduct all prescribed inspections before operating the machine.

- In case of malfunctions, follow standard shutdown procedures immediately.

Table of Content of TB290 Instructions Manual

I. GENERAL

II. SPECIFICATIONS

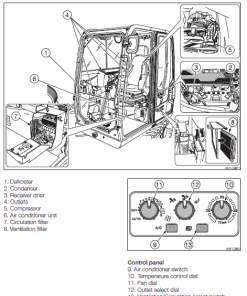

III. MACHINE CONFIGURATION

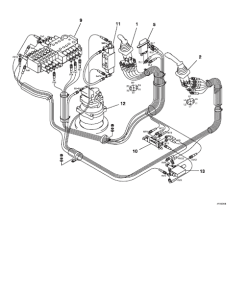

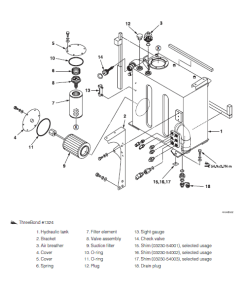

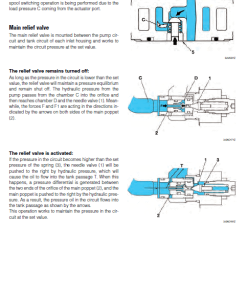

IV. HYDRAULIC UNITS

V. TROUBLESHOOTING

VI. ENGINE

Extract from the Service Manual

| Symptoms | Major Causes | Remedies |

|---|---|---|

| No discharging operation |

Direction of rotation is incorrect. Hydraulic oil tank level is too low. Clogging in the suction piping or the suction filter. Viscosity of hydraulic oil is too high. |

Rotate in the rated direction. Add oil to the specified level. Clean the piping. Replace with hydraulic oil of proper viscosity. |

| Noise is too loud, unusual sound is heard |

Cavitation due to crushed hose or clogged filter. Joint in suction side is loose and sucking air. Cavitation due to high viscosity of hydraulic oil. Pump and engine are not center-aligned. Frothing of hydraulic oil. |

Remove dirt and correct the crushing. Retighten each joint. Replace with hydraulic oil of proper viscosity. Center them again. Investigate and correct the cause of frothing. |

| Oil leak from the oil seal | Oil seal is deformed, worn out, or damaged. | Replace the oil seal. |

Only logged in customers who have purchased this product may leave a review.

Reviews

There are no reviews yet.