Toyota 6HBW23 Powered Pallet Walkie Service Repair Manual

$31.00

Format: PDF

Language: English

Model: 6HBW23 Powered Pallet Walkie

Serial Number: 22,000 and up

Toyota 6HBW23 Powered Pallet Walkie Service Repair Manual

Product Overview

The Toyota 6HBW23 Powered Pallet Walkie Service Repair Manual is your comprehensive guide for maintaining and repairing the Toyota 6HBW23 model. This manual, available in PDF format and written in English, is designed for pallet walkies with a load capacity of 4,500 lbs and serial numbers 22,000 and above. It contains detailed instructions and procedures for the overhaul of engines, chassis, and material handling systems specifically for the Toyota Electric Powered Forklift 7FBEU15 to 20 series and the 7FBEHU18.

Key Features

- 151 pages of detailed repair instructions

- Covers key aspects of forklift maintenance and repair

- Includes sections on safety, system overview, and planned maintenance

- Detailed troubleshooting guide with electrical codes and tests

Benefits

- Access to the latest information and updates from Toyota Industrial Equipment

- Helps ensure safe and efficient operation of your equipment

- Improves the longevity and performance of the forklift

Usage Recommendations

- Ideal for service technicians responsible for the upkeep of Toyota forklifts

- Can be used as a reference alongside other repair manuals for the most comprehensive understanding

- Regular reference to the manual is recommended for planned maintenance and troubleshooting

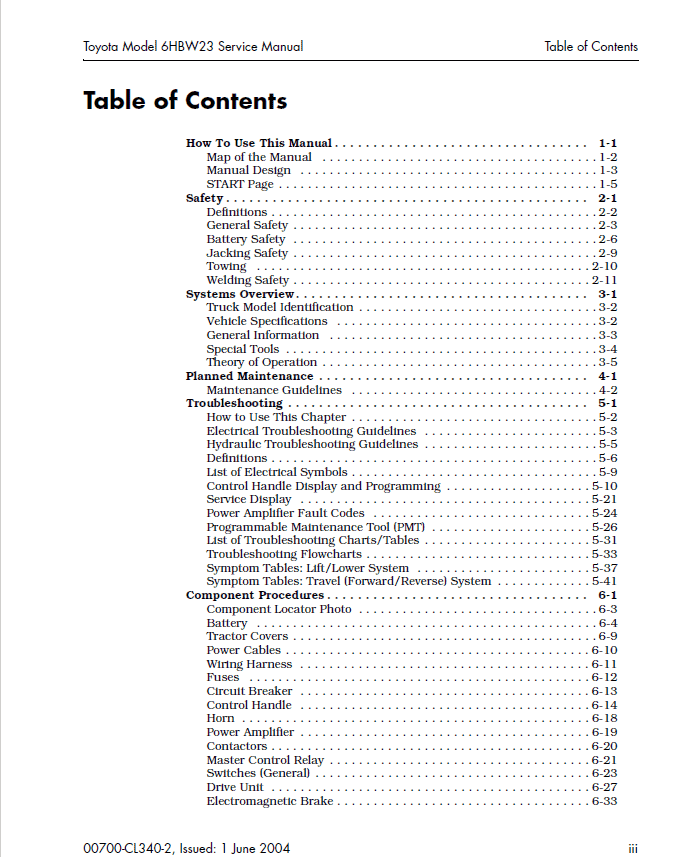

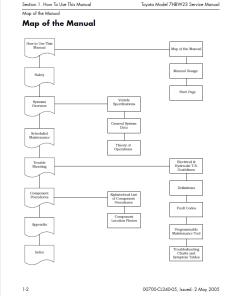

Table of Contents

- How to Use the Manual

- Safety

- System Overview

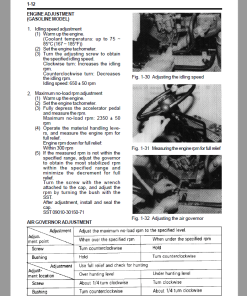

- Planned Maintenance

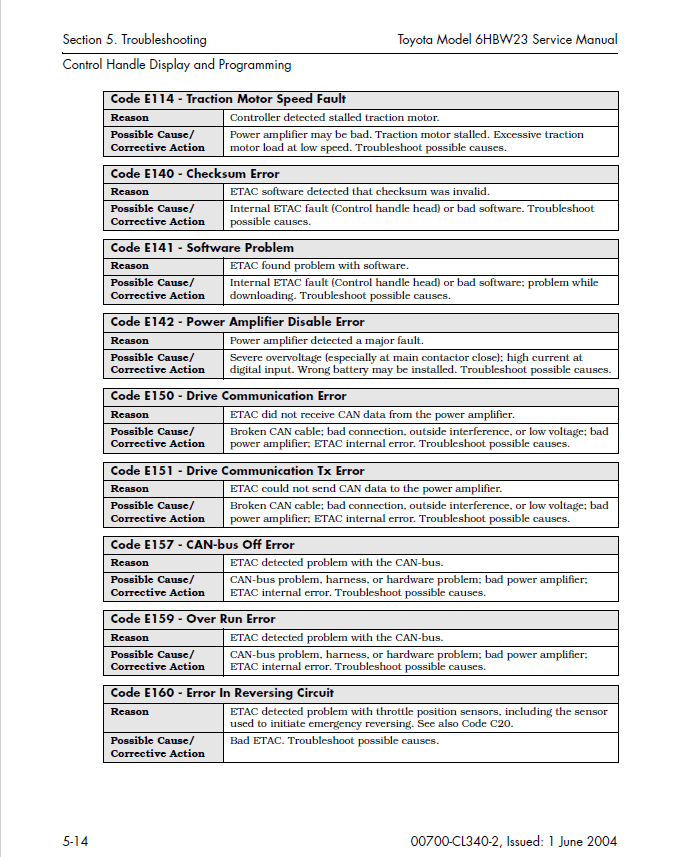

- Troubleshooting

- Electrical Codes and Tests

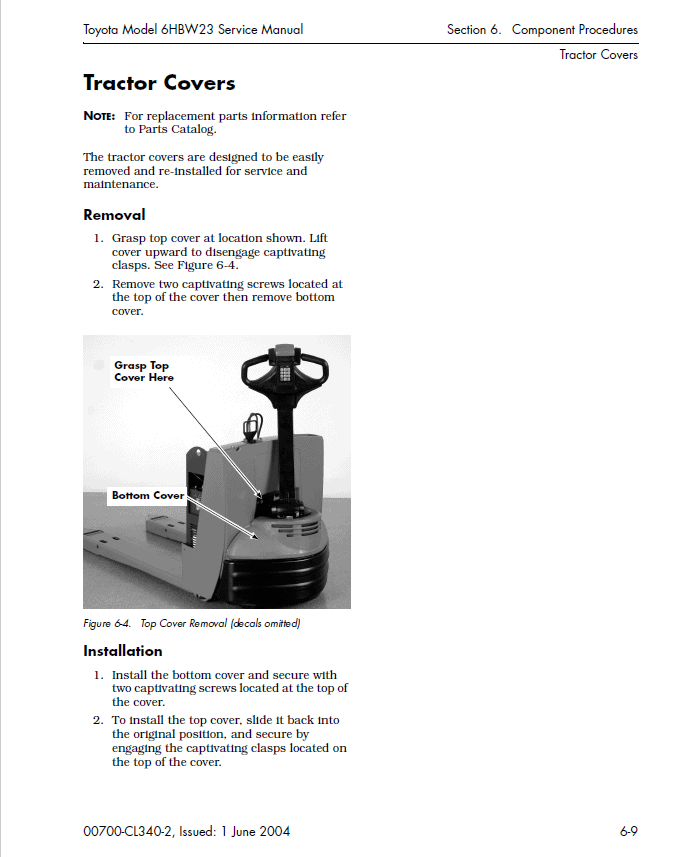

- Component Procedures

- Theory of Operation

- Appendix

- Index

System Operations

Truck Starting

To start the truck, ensure the battery is connected. Switch the Master Control to the ON position, enter the PIN-key code into the keypad, and press the green ON (|) key. Alternatively, use the optional key switch to turn it ON. Refer to the u201cService Displayu201d section on page 5-21 for more details.

Lift/Lower

The lift/lower system utilizes an electrically operated hydraulic pump assembly and associated components. The system features a positive displacement rotary gear pump with a reservoir mounted to an adapter, driven by a DC electric motor on the opposite side of the adapter. It includes an adjustable relief valve, a check valve, and a solenoid-operated lowering valve, ensuring the forks remain elevated by preventing hydraulic fluid return to the reservoir through the closed solenoid and check valves.

Only logged in customers who have purchased this product may leave a review.

Related products

Toyota Forklift

Toyota 7FDU35, 7FDU45, 7FDU60, 7FDU70, 7FDU80, 7FDKU40, 7FDAU50 Forklift Repair Manual

Toyota Forklift

Toyota FGC33, FGC35, FDG40, FGC45 Forklift Repair Service Manual

Toyota Forklift

Still Electric Forklift Truck RX50: RX50-10, RX50-13, RX-50-15, RX50-16 Repair Manual

Still Electric Forklift Truck RX50: RX50-10, RX50-13, RX-50-15, RX50-16 Repair Manual

Reviews

There are no reviews yet.