Volvo EC250D NL Excavator Repair Service Manual

$59.00

This comprehensive Repair Service Manual is essential for routine maintenance and in-depth repairs of the Volvo EC250D NL Excavator. Spanning 2441 pages, this manual ensures you have detailed guidance at your fingertips.

EC250D NL Service Information Guide

Product Overview

The EC250D NL Service Information Guide is a comprehensive resource designed to provide detailed insights into various components and systems of the EC250D NL machine. It is an essential tool for maintenance, service, and operation professionals, ensuring optimal functionality and safety of the machinery.

Key Features

- General Information

- Complete Machine Description

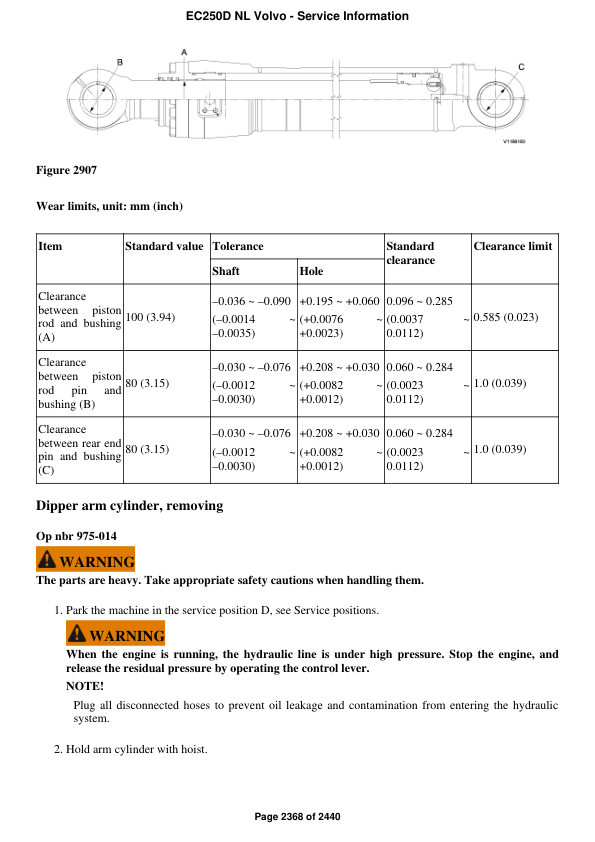

- Specifications

- Standard Time Allocations

- Tools and Miscellaneous Details

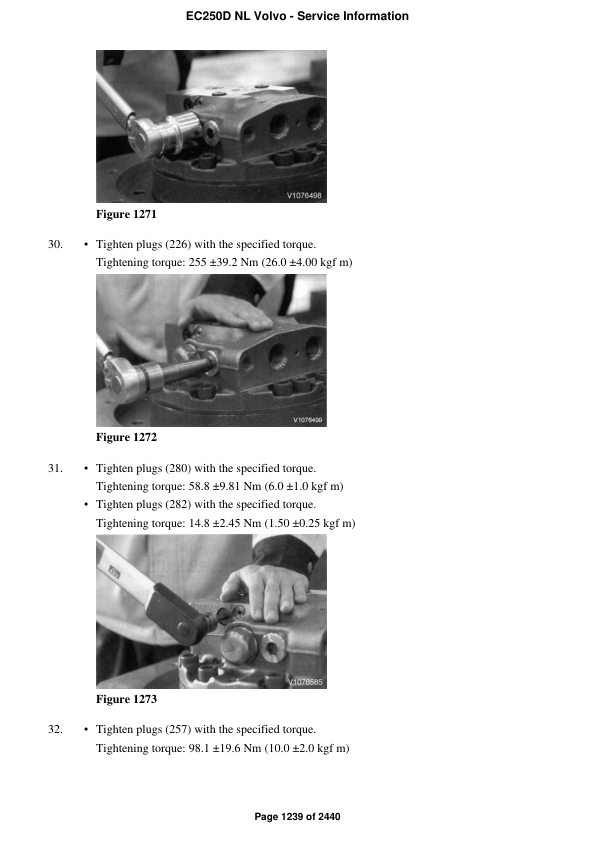

- Service Instructions

- Safety Instructions

- Standard Parts & Service

- Fluids: Lubricant, Fuel, and Others

- General Service Information (Sections 171 – 179)

- Arrival Inspections and Delivery Service

- Maintenance with Condition Testing

- Emergency Measures: Jump Starting

- Engine & Components

- General Engine and Installation Information

- Detailed Components: Cylinder Block, Crankshaft, Valve Mechanism, etc.

- Lubricating System Details

- Fuel System Components and Functionality

- Inlet & Exhaust Systems including Turbo Charger and Catalytic Converter

- Cooling System Specifications and Components

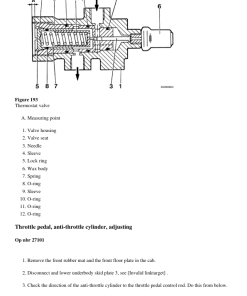

- Engine Control Mechanisms

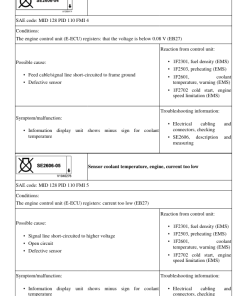

- Electrical Systems

- Electrical and Warning Systems

- Battery and Energy Storage Systems

- Alternator and Charging Systems

- Lighting and Other Electrical Equipment

- Cable, Fuse, and Relay Information

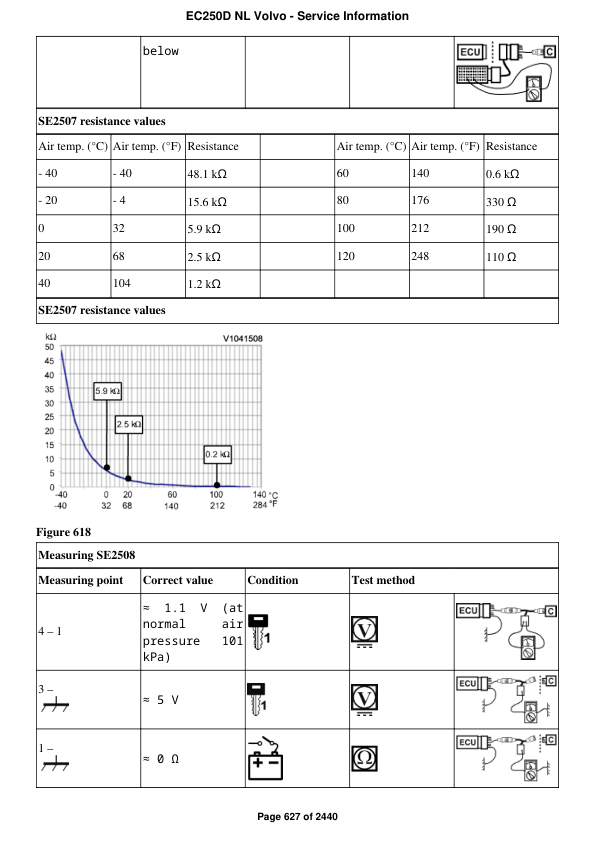

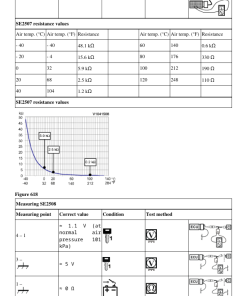

- Instrumentation and Sensor Systems

- Power Transmission

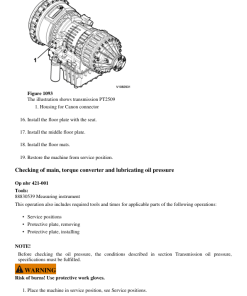

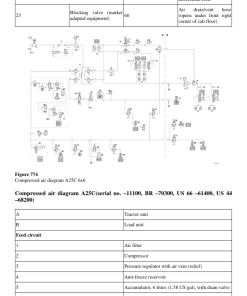

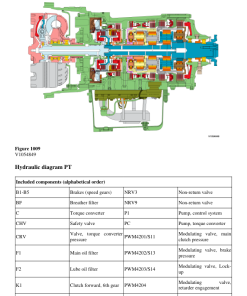

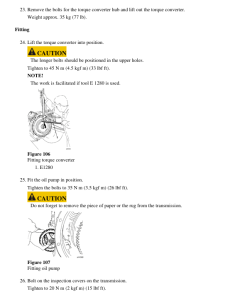

- Transmission Details: Gearbox and Hydrostatic Drive

- Swing System and Center Passage Components

- Structural and Suspension Systems

- Frame Information and Protection Features

- Wheels, Tracks, Tyres, and associated components

- Machinery House & Cab

- Cab Structure, Doors, and Trim Parts

- Engine Hood and Exterior Equipment

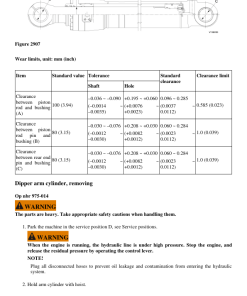

- Hydraulic Systems

- Working Hydraulics and Servo Systems

- Hydraulic Pump and Equipment Information

- Mechanical Attachments

- Attachment Bracket and Buckets

- Excavation Units and Link Systems

- Additional Features

- Fire Protection and Anti-Theft Systems

- Automatic Lubrication System

Benefits

- Ensures proper maintenance and longevity of equipment

- Improves safety through comprehensive safety instructions

- Facilitates efficient servicing with detailed system guides

- Enhances operational understanding of machinery components

Usage Recommendations

- Regularly consult the guide for maintenance schedules and instructions

- Utilize the service instructions for troubleshooting and repairs

- Follow safety guidelines diligently to prevent accidents

- Ensure correct fluid levels and use approved lubricants for optimal performance

Only logged in customers who have purchased this product may leave a review.

Related products

Articulated Dump Truck

Articulated Dump Truck

Articulated Dump Truck

Articulated Dump Truck

Articulated Dump Truck

Articulated Dump Truck

Articulated Dump Truck

Articulated Dump Truck

Volvo A20 6×4 BM Articulated Dump Truck Repair Service Manual

Reviews

There are no reviews yet.