-

×

Caterpillar CAT CS-663E, CP-663E Vibratory Compactor Service Repair Manual (ASF00001 and up)

$350.00

Caterpillar CAT CS-663E, CP-663E Vibratory Compactor Service Repair Manual (ASF00001 and up)

$350.00 -

×

Caterpillar CAT CB-534C Vibratory Compactor Service Repair Manual (1WS00001 and up)

$200.00

Caterpillar CAT CB-534C Vibratory Compactor Service Repair Manual (1WS00001 and up)

$200.00 -

×

Caterpillar CAT CB-534D Vibratory Compactor Service Repair Manual (C8M00001 and up)

$150.00

Caterpillar CAT CB-534D Vibratory Compactor Service Repair Manual (C8M00001 and up)

$150.00 -

×

Caterpillar CAT CS-433E, CP-433E Vibratory Compactor Service Repair Manual (CYE00001 and up)

$200.00

Caterpillar CAT CS-433E, CP-433E Vibratory Compactor Service Repair Manual (CYE00001 and up)

$200.00 -

×

Ford 2600, 2610, 2810 Tractor Service Manual

$34.00

Ford 2600, 2610, 2810 Tractor Service Manual

$34.00 -

×

John Deere Skidder Parts Catalog Manual PC1524

$45.00

John Deere Skidder Parts Catalog Manual PC1524

$45.00 -

×

Caterpillar CAT CB-534B Vibratory Compactor Service Repair Manual (5RN00001 and up)

$50.00

Caterpillar CAT CB-534B Vibratory Compactor Service Repair Manual (5RN00001 and up)

$50.00 -

×

New Holland D150 Bulldozer Dozer Service Manual

$32.00

New Holland D150 Bulldozer Dozer Service Manual

$32.00 -

×

Caterpillar CAT CS-683E Vibratory Compactor Service Repair Manual (AGR00001 and up)

$200.00

Caterpillar CAT CS-683E Vibratory Compactor Service Repair Manual (AGR00001 and up)

$200.00 -

×

Caterpillar CAT CS-573E, CP-573E Vibratory Compactor Service Repair Manual (CNN00001 and up)

$55.00

Caterpillar CAT CS-573E, CP-573E Vibratory Compactor Service Repair Manual (CNN00001 and up)

$55.00 -

×

Waratah HTH450 Harvesting Heads Parts Catalog Manual

$40.00

Waratah HTH450 Harvesting Heads Parts Catalog Manual

$40.00 -

×

Caterpillar CAT C27 Engine Machine Service Repair Manual (NZG00001 and up)

$50.00

Caterpillar CAT C27 Engine Machine Service Repair Manual (NZG00001 and up)

$50.00 -

×

John Deere 450C Crawler Repair Technical Manual (TM1102)

$111.00

John Deere 450C Crawler Repair Technical Manual (TM1102)

$111.00 -

×

Komatsu D31-16, D31S-16, D31Q-16 Dozer Service Manual

$66.00

Komatsu D31-16, D31S-16, D31Q-16 Dozer Service Manual

$66.00 -

×

OM PIMESPO FIAT CSR, TLR, CSRi, TSR, CSR12ac, CSR16ac Workshop Repair Manual

$32.00

OM PIMESPO FIAT CSR, TLR, CSRi, TSR, CSR12ac, CSR16ac Workshop Repair Manual

$32.00 -

×

JCB FM30 Mower Service Manual

$30.50

JCB FM30 Mower Service Manual

$30.50 -

×

Kubota KX121-3, KX161-3 Excavator Workshop Service Manual

$35.00

Kubota KX121-3, KX161-3 Excavator Workshop Service Manual

$35.00 -

×

Komatsu D20PL-7, D20PLL-7, D20AG-7, D20P-7, D20PG-7A Dozer Manual

$34.00

Komatsu D20PL-7, D20PLL-7, D20AG-7, D20P-7, D20PG-7A Dozer Manual

$34.00 -

×

Caterpillar CAT CB-534D Vibratory Compactor Service Repair Manual (EAA00001 and up)

$50.00

Caterpillar CAT CB-534D Vibratory Compactor Service Repair Manual (EAA00001 and up)

$50.00 -

×

Caterpillar CAT CB-335D Vibratory Compactor Service Repair Manual (D4E00001 and up)

$50.00

Caterpillar CAT CB-335D Vibratory Compactor Service Repair Manual (D4E00001 and up)

$50.00 -

×

Linde H100, H120, H136, H150, H160 Forklift 354 Series Repair Service Manual

$33.00

Linde H100, H120, H136, H150, H160 Forklift 354 Series Repair Service Manual

$33.00 -

×

Still Electric Forklift Truck RX70: RX70-16, RX70-18, RX70-20 Repair Manual

$31.00

Still Electric Forklift Truck RX70: RX70-16, RX70-18, RX70-20 Repair Manual

$31.00 -

×

Hyster J40XM, J50XM, J60XM, J65XM Forklift Truck A216 Series Repair Manual (USA)

$45.00

Hyster J40XM, J50XM, J60XM, J65XM Forklift Truck A216 Series Repair Manual (USA)

$45.00 -

×

Caterpillar CAT CB-534C Vibratory Compactor Service Repair Manual (5HN00001 and up)

$250.00

Caterpillar CAT CB-534C Vibratory Compactor Service Repair Manual (5HN00001 and up)

$250.00 -

×

John Deere 2048HV, 2254HV, 2554HV Sabre Technical Manual

$30.00

John Deere 2048HV, 2254HV, 2554HV Sabre Technical Manual

$30.00 -

×

Kubota U20-3, U25-3 Excavator Workshop Manual

$34.00

Kubota U20-3, U25-3 Excavator Workshop Manual

$34.00 -

×

John Deere 350, 350B Crawler Tractor Repair Technical Manual (TM1032 and SM2063)

$74.00

John Deere 350, 350B Crawler Tractor Repair Technical Manual (TM1032 and SM2063)

$74.00 -

×

Caterpillar CAT CS-583C Vibratory Compactor Service Repair Manual (7MN00001 and up)

$50.00

Caterpillar CAT CS-583C Vibratory Compactor Service Repair Manual (7MN00001 and up)

$50.00 -

×

John Deere 544E, 624E, 544ETC, 544ELL Loaders Parts Catalog Manual - PC2170

$50.00

John Deere 544E, 624E, 544ETC, 544ELL Loaders Parts Catalog Manual - PC2170

$50.00 -

×

Caterpillar CAT 302 CR Mini Hydraulic Excavator Service Repair Manual (RHM00001 and up)

$70.00

Caterpillar CAT 302 CR Mini Hydraulic Excavator Service Repair Manual (RHM00001 and up)

$70.00 -

×

Caterpillar CAT CS-563D Vibratory Compactor Service Repair Manual (1SZ00001 and up)

$100.00

Caterpillar CAT CS-563D Vibratory Compactor Service Repair Manual (1SZ00001 and up)

$100.00 -

×

Caterpillar CAT 3406B Truck Engine Service Repair Manual (2EK00001 and up)

$50.00

Caterpillar CAT 3406B Truck Engine Service Repair Manual (2EK00001 and up)

$50.00 -

×

Caterpillar CAT 323F, 323F L Excavator Service Repair Manual (KBY00001 and up)

$80.00

Caterpillar CAT 323F, 323F L Excavator Service Repair Manual (KBY00001 and up)

$80.00 -

×

JCB 8280, 8310 Fastrac Service Manual

$35.00

JCB 8280, 8310 Fastrac Service Manual

$35.00 -

×

Doosan Daewoo DX140W, DX160W Excavator Service Manual

$34.00

Doosan Daewoo DX140W, DX160W Excavator Service Manual

$34.00 -

×

Caterpillar CAT 330C FM Excavator Service Repair Manual (B3M00001 and up)

$80.00

Caterpillar CAT 330C FM Excavator Service Repair Manual (B3M00001 and up)

$80.00 -

×

Takeuchi TB138 Compact Excavator Service Manual

$35.00

Takeuchi TB138 Compact Excavator Service Manual

$35.00 -

×

Caterpillar CAT D9N Track Type Tractor Service Repair Manual (1JD00001 and up)

$70.00

Caterpillar CAT D9N Track Type Tractor Service Repair Manual (1JD00001 and up)

$70.00 -

×

John Deere 555 Crawler Loader Repair Technical Manual (TM1111)

$114.00

John Deere 555 Crawler Loader Repair Technical Manual (TM1111)

$114.00 -

×

Caterpillar CAT 320D Excavator Service Repair Manual (JPD00001 and up)

$70.00

Caterpillar CAT 320D Excavator Service Repair Manual (JPD00001 and up)

$70.00 -

×

OM Pimespo Engine 3.0L For Forklift Trucks Repair Rules Manual

$25.00

OM Pimespo Engine 3.0L For Forklift Trucks Repair Rules Manual

$25.00 -

×

Caterpillar CAT CS-433E, CP-433E Vibratory Compactor Service Repair Manual (DAC00001 and up)

$100.00

Caterpillar CAT CS-433E, CP-433E Vibratory Compactor Service Repair Manual (DAC00001 and up)

$100.00 -

×

Timberjack 608 Carriers Service Repair Manual (977031 - 987326)

$38.00

Timberjack 608 Carriers Service Repair Manual (977031 - 987326)

$38.00 -

×

John Deere 1842GV, 1842HV Sabre Yard Tractors Repair Technical Manual (TM1740)

$58.00

John Deere 1842GV, 1842HV Sabre Yard Tractors Repair Technical Manual (TM1740)

$58.00 -

×

Caterpillar CAT 345C, 345C L Hydraulic Excavator Service Repair Manual (PJW00001 and up)

$80.00

Caterpillar CAT 345C, 345C L Hydraulic Excavator Service Repair Manual (PJW00001 and up)

$80.00 -

×

New Holland D255 Bulldozer Dozer Service Manual

$33.00

New Holland D255 Bulldozer Dozer Service Manual

$33.00 -

×

Caterpillar CAT CB-534D, CB-534DXW Vibratory Compactor Service Repair Manual (FEA00001 and up)

$100.00

Caterpillar CAT CB-534D, CB-534DXW Vibratory Compactor Service Repair Manual (FEA00001 and up)

$100.00 -

×

Caterpillar CAT CS-433E, CP-433E Vibratory Compactor Service Repair Manual (BTT00001 and up)

$100.00

Caterpillar CAT CS-433E, CP-433E Vibratory Compactor Service Repair Manual (BTT00001 and up)

$100.00 -

×

John Deere 450E, 455E Crawler Bulldozer Loader Technical Manual

$114.00

John Deere 450E, 455E Crawler Bulldozer Loader Technical Manual

$114.00 -

×

Caterpillar CAT CB-334E, CB-335E Vibratory Compactor Service Repair Manual (C5J00001 and up)

$150.00

Caterpillar CAT CB-334E, CB-335E Vibratory Compactor Service Repair Manual (C5J00001 and up)

$150.00 -

×

Caterpillar CAT CB-534D Vibratory Compactor Service Repair Manual (C4B00001 and up)

$100.00

Caterpillar CAT CB-534D Vibratory Compactor Service Repair Manual (C4B00001 and up)

$100.00 -

×

Caterpillar CAT 349D2, 349D2 L Excavator Service Repair Manual (YAG00001 and up)

$80.00

Caterpillar CAT 349D2, 349D2 L Excavator Service Repair Manual (YAG00001 and up)

$80.00 -

×

Caterpillar CAT CS-531D Vibratory Compactor Service Repair Manual (AGH00001 and up)

$50.00

Caterpillar CAT CS-531D Vibratory Compactor Service Repair Manual (AGH00001 and up)

$50.00 -

×

John Deere 1438, 1542, 1642, 1646 Sabre Lawn Tractors Technical Manual

$56.00

John Deere 1438, 1542, 1642, 1646 Sabre Lawn Tractors Technical Manual

$56.00 -

×

John Deere 755A Crawler Loader Repair Technical Manual (TM1231)

$76.00

John Deere 755A Crawler Loader Repair Technical Manual (TM1231)

$76.00 -

×

Still Diesel LPG Forklift Trucks RC40: RC40-16, RC40-18, RC40-20 Workshop Manual

$34.00

Still Diesel LPG Forklift Trucks RC40: RC40-16, RC40-18, RC40-20 Workshop Manual

$34.00 -

×

Kubota KX080-3 Excavator Workshop Service Manual

$68.00

Kubota KX080-3 Excavator Workshop Service Manual

$68.00 -

×

Caterpillar CAT 3304B Marine Engine Service Repair Manual (1NS00001 and up)

$50.00

Caterpillar CAT 3304B Marine Engine Service Repair Manual (1NS00001 and up)

$50.00 -

×

Tigercat 720E Feller Buncher Repair Service Manual (SN 7204401 - 7205500)

$35.00

Tigercat 720E Feller Buncher Repair Service Manual (SN 7204401 - 7205500)

$35.00 -

×

John Deere 953J Tracked Feller Bunchers Parts Catalog Manual - PC10083

$85.00

John Deere 953J Tracked Feller Bunchers Parts Catalog Manual - PC10083

$85.00 -

×

John Deere X940, X948, X949 Lawn Tractor Repair Manual (S.N 060001 - ) (TM147919)

$44.00

John Deere X940, X948, X949 Lawn Tractor Repair Manual (S.N 060001 - ) (TM147919)

$44.00 -

×

Caterpillar CAT 3406E Generator Set Engine Service Repair Manual (9NN00001 and up)

$50.00

Caterpillar CAT 3406E Generator Set Engine Service Repair Manual (9NN00001 and up)

$50.00 -

×

John Deere 750B, 850B Crawler Repair Technical Manual (TM1476)

$76.00

John Deere 750B, 850B Crawler Repair Technical Manual (TM1476)

$76.00 -

×

Caterpillar CAT 336D L, 336D LN Excavator Service Repair Manual (MYG00001 and up)

$80.00

Caterpillar CAT 336D L, 336D LN Excavator Service Repair Manual (MYG00001 and up)

$80.00 -

×

John Deere 750 Crawler Repair Technical Manual (TM1136)

$74.00

John Deere 750 Crawler Repair Technical Manual (TM1136)

$74.00 -

×

New Holland W50 Wheeled Loader Service Manual

$34.00

New Holland W50 Wheeled Loader Service Manual

$34.00 -

×

Kubota B2410, B2710, B2910, B7800HSD Tractor Service Manual

$34.50

Kubota B2410, B2710, B2910, B7800HSD Tractor Service Manual

$34.50 -

×

Liebherr A900, A902, A912, A922, A942 Hydraulic Excavator Service Manual

$36.00

Liebherr A900, A902, A912, A922, A942 Hydraulic Excavator Service Manual

$36.00 -

×

Volvo MC70B Skid Steer Loader Repair Service Manual

$42.00

Volvo MC70B Skid Steer Loader Repair Service Manual

$42.00 -

×

Still SXD-20 and SXH-20 Pallet Truck Workshop Circuit Repair Manual

$35.00

Still SXD-20 and SXH-20 Pallet Truck Workshop Circuit Repair Manual

$35.00 -

×

Caterpillar CAT 349E L, 349E L VG Excavator Service Repair Manual (ETC00001 and up)

$80.00

Caterpillar CAT 349E L, 349E L VG Excavator Service Repair Manual (ETC00001 and up)

$80.00 -

×

Caterpillar CAT 349D, 349D L Excavator Service Repair Manual (NNF00001 and up)

$80.00

Caterpillar CAT 349D, 349D L Excavator Service Repair Manual (NNF00001 and up)

$80.00 -

×

Kubota KH36, KH41, KH51, KH61 Excavator Workshop Manual

$32.00

Kubota KH36, KH41, KH51, KH61 Excavator Workshop Manual

$32.00 -

×

Timberjack C90 Delimbers (SN AA9772-AC9043) Parts Catalog Manual - WC299772

$30.00

Timberjack C90 Delimbers (SN AA9772-AC9043) Parts Catalog Manual - WC299772

$30.00 -

×

Caterpillar CAT 3116 Truck Engine Service Repair Manual (9CJ00001 and up)

$45.00

Caterpillar CAT 3116 Truck Engine Service Repair Manual (9CJ00001 and up)

$45.00 -

×

Caterpillar CAT 3512 Petroleum Engine Service Repair Manual (PE300001 and up)

$50.00

Caterpillar CAT 3512 Petroleum Engine Service Repair Manual (PE300001 and up)

$50.00 -

×

JCB Midi CX Backhoe Loader Service Manual

$34.00

JCB Midi CX Backhoe Loader Service Manual

$34.00 -

×

Takeuchi TB230 Compact Excavator Service Manual

$31.00

Takeuchi TB230 Compact Excavator Service Manual

$31.00 -

×

John Deere 724K 4WD Engine S2 & T3 Loader Technical Manual (S.N. before 641522)

$60.00

John Deere 724K 4WD Engine S2 & T3 Loader Technical Manual (S.N. before 641522)

$60.00 -

×

Caterpillar CAT C4.4 Engine Machine Service Repair Manual (E7A00001 and up)

$45.00

Caterpillar CAT C4.4 Engine Machine Service Repair Manual (E7A00001 and up)

$45.00 -

×

Caterpillar CAT C32B Marine Engine Service Repair Manual (HPT00001 and up)

$50.00

Caterpillar CAT C32B Marine Engine Service Repair Manual (HPT00001 and up)

$50.00 -

×

Caterpillar CAT CS-423E Vibratory Compactor Service Repair Manual (BWG00001 and up)

$150.00

Caterpillar CAT CS-423E Vibratory Compactor Service Repair Manual (BWG00001 and up)

$150.00 -

×

John Deere 450D, 455D Crawler Bulldozer Loader Technical Manual

$38.00

John Deere 450D, 455D Crawler Bulldozer Loader Technical Manual

$38.00 -

×

Caterpillar CAT 336D L, 336D LN Excavator Service Repair Manual (KDJ00001 and up)

$80.00

Caterpillar CAT 336D L, 336D LN Excavator Service Repair Manual (KDJ00001 and up)

$80.00 -

×

Caterpillar CAT CB-534B Vibratory Compactor Service Repair Manual (4JL00001 and up)

$100.00

Caterpillar CAT CB-534B Vibratory Compactor Service Repair Manual (4JL00001 and up)

$100.00 -

×

New Holland E140CSR Excavator Service Manual

$72.00

New Holland E140CSR Excavator Service Manual

$72.00 -

×

Caterpillar CAT CS-573C Vibratory Compactor Service Repair Manual (6LN00001 and up)

$100.00

Caterpillar CAT CS-573C Vibratory Compactor Service Repair Manual (6LN00001 and up)

$100.00 -

×

Bobcat 116 Excavator Service Manual

$29.00

Bobcat 116 Excavator Service Manual

$29.00 -

×

Bobcat 335 Compact Excavator Service Manual

$34.00

Bobcat 335 Compact Excavator Service Manual

$34.00 -

×

Caterpillar CAT 336F 336F L, 336F LN Excavator Service Repair Manual (LJY00001 and up)

$80.00

Caterpillar CAT 336F 336F L, 336F LN Excavator Service Repair Manual (LJY00001 and up)

$80.00 -

×

New Holland E235SR Excavator Service Manual

$36.00

New Holland E235SR Excavator Service Manual

$36.00 -

×

Caterpillar CAT 306E Mini Hydraulic Excavator Service Repair Manual (FHL00001 and up)

$70.00

Caterpillar CAT 306E Mini Hydraulic Excavator Service Repair Manual (FHL00001 and up)

$70.00 -

×

Caterpillar CAT CS-423E Vibratory Compactor Service Repair Manual (CFX00001 and up)

$100.00

Caterpillar CAT CS-423E Vibratory Compactor Service Repair Manual (CFX00001 and up)

$100.00 -

×

Bobcat 450 and 453 Skid-Steer Loader Service Manual

$32.00

Bobcat 450 and 453 Skid-Steer Loader Service Manual

$32.00 -

×

Massey Ferguson 1523 Tractors Service Workshop Manual

$34.00

Massey Ferguson 1523 Tractors Service Workshop Manual

$34.00 -

×

Massey Ferguson 1125, 1140, 1145, 1240, 1250, 1260 Tractors Workshop Manual

$34.00

Massey Ferguson 1125, 1140, 1145, 1240, 1250, 1260 Tractors Workshop Manual

$34.00 -

×

Liebherr R906, R916, R926 Classic & Advance Excavator Service Manual

$35.00

Liebherr R906, R916, R926 Classic & Advance Excavator Service Manual

$35.00 -

×

Liebherr A900, A902, A912, A922, A932 Litronic Excavator Service Manual

$36.00

Liebherr A900, A902, A912, A922, A932 Litronic Excavator Service Manual

$36.00 -

×

John Deere 1948GV, 1948HV, 2148HV, 2354HV, 2554HV Sabre Tractors Technical Manual

$28.00

John Deere 1948GV, 1948HV, 2148HV, 2354HV, 2554HV Sabre Tractors Technical Manual

$28.00 -

×

AGCO ST60A Tractor Service Manual

$36.00

AGCO ST60A Tractor Service Manual

$36.00 -

×

Caterpillar CAT D20D, D250D Articulated Dump Truck Service Repair Manual (6NG00001 and up)

$70.00

Caterpillar CAT D20D, D250D Articulated Dump Truck Service Repair Manual (6NG00001 and up)

$70.00 -

×

Bobcat 324 Compact Excavator Service Manual

$34.00

Bobcat 324 Compact Excavator Service Manual

$34.00 -

×

John Deere 450 Crawler Tractor Repair Technical Manual (SM2064)

$34.00

John Deere 450 Crawler Tractor Repair Technical Manual (SM2064)

$34.00 -

×

Timberjack 4500 Delimber Loader Attachments Parts Catalog Manual

$20.00

Timberjack 4500 Delimber Loader Attachments Parts Catalog Manual

$20.00 -

×

John Deere 9620R Scraper Tractors (SN 015000-) Parts Catalog Manual - PC12221

$60.00

John Deere 9620R Scraper Tractors (SN 015000-) Parts Catalog Manual - PC12221

$60.00 -

×

Caterpillar CAT CP-533C, CS-533C Vibratory Compactor Service Repair Manual (2XN00001 and up)

$100.00

Caterpillar CAT CP-533C, CS-533C Vibratory Compactor Service Repair Manual (2XN00001 and up)

$100.00 -

×

New Holland E40.2SR and E50.2SR Mini Excavator Service Manual

$35.00

New Holland E40.2SR and E50.2SR Mini Excavator Service Manual

$35.00 -

×

Caterpillar CAT 336D, 336D L Excavator Service Repair Manual (KKT00001 and up)

$80.00

Caterpillar CAT 336D, 336D L Excavator Service Repair Manual (KKT00001 and up)

$80.00 -

×

AGCO ST22A Compact Tractor Service Manual

$26.00

AGCO ST22A Compact Tractor Service Manual

$26.00 -

×

Caterpillar CAT CB10 Asphalt Compactor Service Repair Manual (L9R00001 and up)

$70.00

Caterpillar CAT CB10 Asphalt Compactor Service Repair Manual (L9R00001 and up)

$70.00 -

×

Still MX-X Order Picking Truck Generation 3, 48v and 80v Workshop Repair Manual

$33.00

Still MX-X Order Picking Truck Generation 3, 48v and 80v Workshop Repair Manual

$33.00 -

×

John Deere 850 Crawler Repair Technical Manual (TM1164)

$33.00

John Deere 850 Crawler Repair Technical Manual (TM1164)

$33.00 -

×

Still Electric Forklift Truck RX70: RX70-40, RX70-45, RX70-50 Repair Manual

$34.00

Still Electric Forklift Truck RX70: RX70-40, RX70-45, RX70-50 Repair Manual

$34.00 -

×

Caterpillar CAT CB-334E, CB-335E Vibratory Compactor Service Repair Manual (C3F00001 and up)

$45.00

Caterpillar CAT CB-334E, CB-335E Vibratory Compactor Service Repair Manual (C3F00001 and up)

$45.00 -

×

Fendt 1149MT, 1154MT, 1159MT, 1165MT Tractor Service Manual

$40.00

Fendt 1149MT, 1154MT, 1159MT, 1165MT Tractor Service Manual

$40.00 -

×

Timberjack S546 Felling Heads (SN 980001-999999) Parts Catalog Manual - WCF291212

$20.00

Timberjack S546 Felling Heads (SN 980001-999999) Parts Catalog Manual - WCF291212

$20.00 -

×

Caterpillar CAT 313D2 Excavator Service Repair Manual (PLD00001 and up)

$80.00

Caterpillar CAT 313D2 Excavator Service Repair Manual (PLD00001 and up)

$80.00 -

×

Caterpillar CAT C27 Engine Service Repair Manual (TWM00001 and up)

$50.00

Caterpillar CAT C27 Engine Service Repair Manual (TWM00001 and up)

$50.00 -

×

Kubota U35S, US35-3S, US45-3S Excavator Workshop Manual

$29.50

Kubota U35S, US35-3S, US45-3S Excavator Workshop Manual

$29.50 -

×

Hyster J2.00XM, J2.50XM, J3.00XM, J3.20XM Electric Forklift Truck A416 Series Repair Manual

$45.00

Hyster J2.00XM, J2.50XM, J3.00XM, J3.20XM Electric Forklift Truck A416 Series Repair Manual

$45.00 -

×

Caterpillar CAT 3116 Marine Engine Service Repair Manual (4KG00001 and up)

$50.00

Caterpillar CAT 3116 Marine Engine Service Repair Manual (4KG00001 and up)

$50.00 -

×

OM PIMESPO Modo 1,2,3 Series 014 Mid and High-lift Order Pickers Workshop Repair Manual

$27.00

OM PIMESPO Modo 1,2,3 Series 014 Mid and High-lift Order Pickers Workshop Repair Manual

$27.00 -

×

Komatsu WB140-2N and WB150-2N Backhoe Loader Service Manual

$34.50

Komatsu WB140-2N and WB150-2N Backhoe Loader Service Manual

$34.50 -

×

Kubota KX36-3, KX41-3S, KX41-3V Excavator Workshop Manual

$34.00

Kubota KX36-3, KX41-3S, KX41-3V Excavator Workshop Manual

$34.00 -

×

Caterpillar CAT D3 Track-Type Tractor Service Repair Manual (XKW00001 and up)

$70.00

Caterpillar CAT D3 Track-Type Tractor Service Repair Manual (XKW00001 and up)

$70.00 -

×

Caterpillar CAT 3512C Marine Engine Service Repair Manual (PXW00001 and up)

$50.00

Caterpillar CAT 3512C Marine Engine Service Repair Manual (PXW00001 and up)

$50.00 -

×

Caterpillar CAT 336F L, 336F LN Excavator Service Repair Manual (WTZ00001 and up)

$80.00

Caterpillar CAT 336F L, 336F LN Excavator Service Repair Manual (WTZ00001 and up)

$80.00 -

×

Caterpillar CAT AP655F Asphalt Paver Service Repair Manual (P6500001 and up)

$70.00

Caterpillar CAT AP655F Asphalt Paver Service Repair Manual (P6500001 and up)

$70.00 -

×

Caterpillar CAT 330D L Excavator Service Repair Manual (B6H00001 and up)

$80.00

Caterpillar CAT 330D L Excavator Service Repair Manual (B6H00001 and up)

$80.00 -

×

Caterpillar CAT 336 GC Excavator Service Repair Manual (EBJ00001 and up)

$80.00

Caterpillar CAT 336 GC Excavator Service Repair Manual (EBJ00001 and up)

$80.00 -

×

Bobcat 425 and 428 Compact Excavator Service Manual

$34.00

Bobcat 425 and 428 Compact Excavator Service Manual

$34.00 -

×

Koehring 18 Inch, 20 Inch, 22 Inch, 24 Inch Felling Heads Parts Catalog Manual

$40.00

Koehring 18 Inch, 20 Inch, 22 Inch, 24 Inch Felling Heads Parts Catalog Manual

$40.00 -

×

Caterpillar CAT 320D, 320D L Excavator Service Repair Manual (MCH00001 and up)

$70.00

Caterpillar CAT 320D, 320D L Excavator Service Repair Manual (MCH00001 and up)

$70.00 -

×

Caterpillar CAT CS-433E, CP-433E Vibratory Compactor Service Repair Manual (BTY00001 and up)

$50.00

Caterpillar CAT CS-433E, CP-433E Vibratory Compactor Service Repair Manual (BTY00001 and up)

$50.00 -

×

Caterpillar CAT 3512C Marine Engine Service Repair Manual (TKP00001 and up)

$50.00

Caterpillar CAT 3512C Marine Engine Service Repair Manual (TKP00001 and up)

$50.00 -

×

John Deere 544K 4WD Loader Technical Manual (SN. D000001 - D001000)

$60.00

John Deere 544K 4WD Loader Technical Manual (SN. D000001 - D001000)

$60.00 -

×

JCB 354, 360 Tractor Service Manual

$33.50

JCB 354, 360 Tractor Service Manual

$33.50 -

×

JCB 1CX Backhoe Loader Service Manual

$34.00

JCB 1CX Backhoe Loader Service Manual

$34.00 -

×

John Deere ZAXIS210F-LL-6N Log Loaders (SN 1FFDC572__F216001-) Parts Catalog Manual - PC15094

$65.00

John Deere ZAXIS210F-LL-6N Log Loaders (SN 1FFDC572__F216001-) Parts Catalog Manual - PC15094

$65.00 -

×

Caterpillar CAT 336D L Excavator Service Repair Manual (J6D00001 and up)

$80.00

Caterpillar CAT 336D L Excavator Service Repair Manual (J6D00001 and up)

$80.00 -

×

John Deere 644K 4WD Loader Technical Manual (S.N. after C000001 & D000001 - )

$61.00

John Deere 644K 4WD Loader Technical Manual (S.N. after C000001 & D000001 - )

$61.00 -

×

Volvo MC110D Skid Steer Loader Repair Service Manual

$40.00

Volvo MC110D Skid Steer Loader Repair Service Manual

$40.00 -

×

John Deere 450B Crawler Tractor Repair Technical Manual (TM1033)

$35.00

John Deere 450B Crawler Tractor Repair Technical Manual (TM1033)

$35.00 -

×

Hyster E2.2XN, E2.5XN, E3.0XN, E3.2XN, E3.5XN Electric Forklift Truck A268 Series Repair Manual

$49.00

Hyster E2.2XN, E2.5XN, E3.0XN, E3.2XN, E3.5XN Electric Forklift Truck A268 Series Repair Manual

$49.00 -

×

Koehring 746B Standard Felling Heads (SN 1305-1327 & 0012-0508) Parts Catalog Manual - WC701391400

$45.00

Koehring 746B Standard Felling Heads (SN 1305-1327 & 0012-0508) Parts Catalog Manual - WC701391400

$45.00 -

×

Ford Versatile 256, 276, 276II Tractor Service Manual

$33.00

Ford Versatile 256, 276, 276II Tractor Service Manual

$33.00 -

×

Kubota KX080-4 Excavator Workshop Service Manual

$34.00

Kubota KX080-4 Excavator Workshop Service Manual

$34.00 -

×

Caterpillar CAT CS-583D Vibratory Compactor Service Repair Manual (2CZ00001 and up)

$50.00

Caterpillar CAT CS-583D Vibratory Compactor Service Repair Manual (2CZ00001 and up)

$50.00 -

×

Caterpillar CAT CB-534D, CB-534DXW Vibratory Compactor Service Repair Manual (FGH00001 and up)

$50.00

Caterpillar CAT CB-534D, CB-534DXW Vibratory Compactor Service Repair Manual (FGH00001 and up)

$50.00 -

×

New Holland W80 Wheeled Loader Service Manual

$34.00

New Holland W80 Wheeled Loader Service Manual

$34.00 -

×

New Holland W70 Wheeled Loader Service Manual

$34.00

New Holland W70 Wheeled Loader Service Manual

$34.00 -

×

John Deere Tractors 280, 284, 300, 304, 320, 324 Repair Technical Manual

$39.00

John Deere Tractors 280, 284, 300, 304, 320, 324 Repair Technical Manual

$39.00 -

×

Caterpillar CAT 330D, 330D L Excavator Service Repair Manual (FFK00001 and up)

$80.00

Caterpillar CAT 330D, 330D L Excavator Service Repair Manual (FFK00001 and up)

$80.00 -

×

Caterpillar CAT TH255 Telehandler Service Repair Manual

$65.00

Caterpillar CAT TH255 Telehandler Service Repair Manual

$65.00 -

×

Caterpillar CAT 287 Multi Terrain Loader Service Repair Manual (CNY00001 and up)

$70.00

Caterpillar CAT 287 Multi Terrain Loader Service Repair Manual (CNY00001 and up)

$70.00 -

×

Caterpillar CAT 3406B Generator Set Engine Service Repair Manual (4JK00001 and up)

$50.00

Caterpillar CAT 3406B Generator Set Engine Service Repair Manual (4JK00001 and up)

$50.00 -

×

Komatsu D66S-1 Dozer Service Manual

$34.00

Komatsu D66S-1 Dozer Service Manual

$34.00

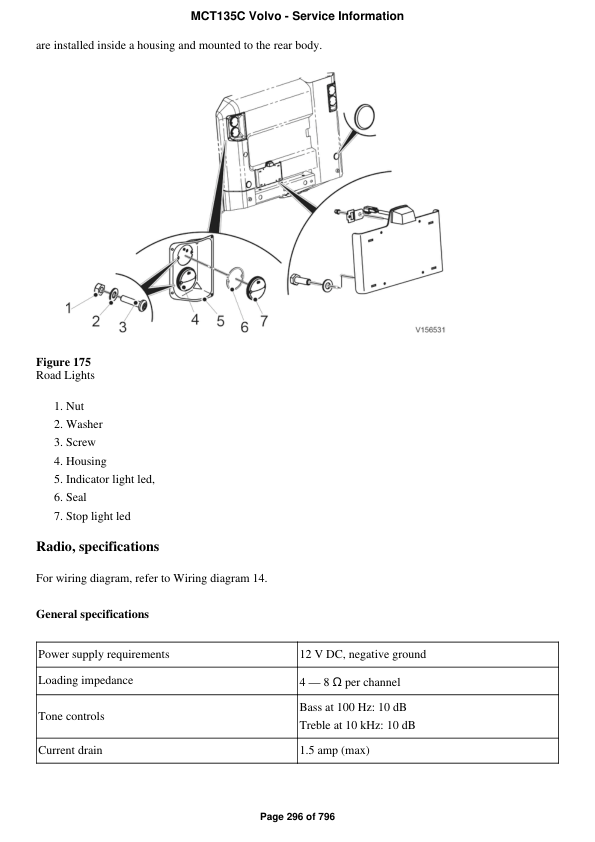

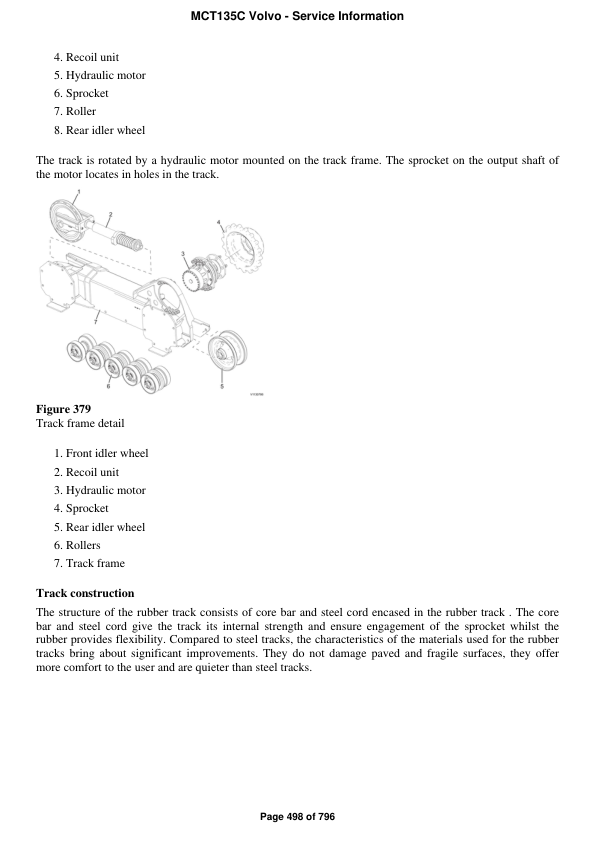

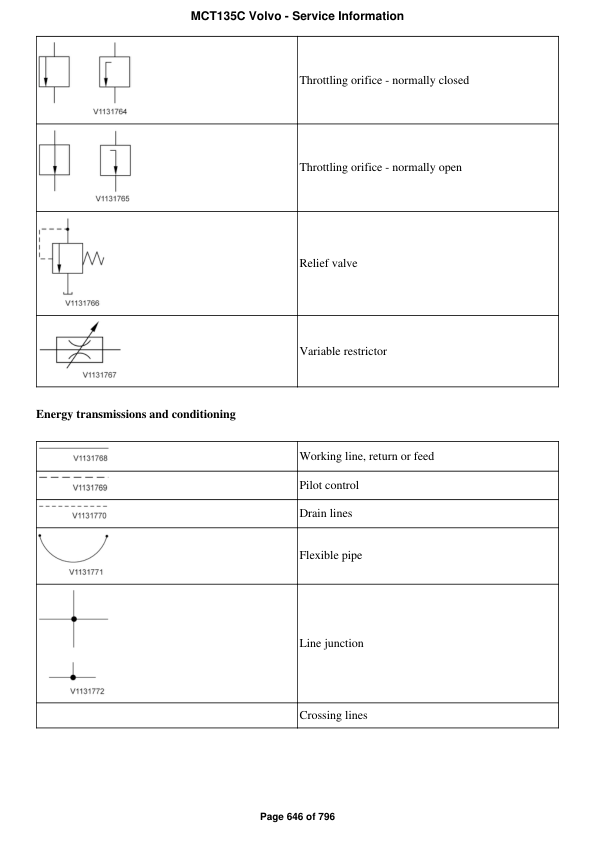

Volvo MCT135C Skid Steer Loader Repair Service Manual

$42.00

Enhance your maintenance skills with the comprehensive Repair Service Manual for the Volvo MCT135C Skid Steer Loader. This detailed 797-page PDF guide provides all the essential information you need.

MCT135C Service Information

Product Overview

The MCT135C is a state-of-the-art machine offering unparalleled performance and reliability. This guide provides comprehensive service information necessary for maintaining and optimizing the machine’s operations.

Table of Contents

General Information

-

Description of the Complete Machine

- Includes all general details about the machine.

-

Specifications

- Comprehensive machine specifications for informed utilization and maintenance.

-

Standard Time

- General time standards for various operational tasks.

-

Standard Parts and Service

- Details on lubricants, fuels, and other required fluids.

-

Service Procedures

- Information on arrival inspections and delivery service procedures.

- Guidelines for regular maintenance.

Engine and Equipment

-

Engine Installation and Function

- General information about engine mounting and its functional aspects.

-

Fuel System

- Overview of the complete fuel management system (range 233-238).

-

Cooling System

- Components include fan, fan shroud, and fan coupling.

-

Electrical and Warning Systems

- Comprehensive electrical system information, including software documents, fault tracing, etc.

-

Battery and Energy Storage

- General information about battery storage and mounting parts.

Power Transmission

-

Hydrostatic Drive

- General information including hydraulic motor and operating systems.

-

Hydraulic Pump and System

- Pump details including travel systems and operating mechanisms.

Chassis and Cab

-

Cab and Structural Components

- General information on cab structure, doors, locks, and other exterior components.

-

Air Conditioning Unit

- Details about the cooling unit and operations within the range 872-877.

Key Features

- Comprehensive service guide for complete machine functionality.

- All-encompassing details on engine, hydraulic systems, and electrical components.

- Easy-to-understand maintenance and service procedures.

Benefits

- Improved machine reliability and performance.

- Extended lifespan through regular maintenance.

- Optimized operational efficiency.

Usage Recommendations

- Regularly review the service information to stay informed about maintenance practices.

- Use only recommended parts and fluids to ensure compatibility and performance.

- Conduct routine inspections to preemptively address wear and tear.

Only logged in customers who have purchased this product may leave a review.

Related products

Articulated Dump Truck

$40.00

Articulated Dump Truck

$48.00

Articulated Dump Truck

$35.00

Articulated Dump Truck

$70.00

Articulated Dump Truck

Volvo A20 6×4 BM Articulated Dump Truck Repair Service Manual

$35.00

Articulated Dump Truck

$37.00

Articulated Dump Truck

$85.00

Articulated Dump Truck

$42.00

Reviews

There are no reviews yet.