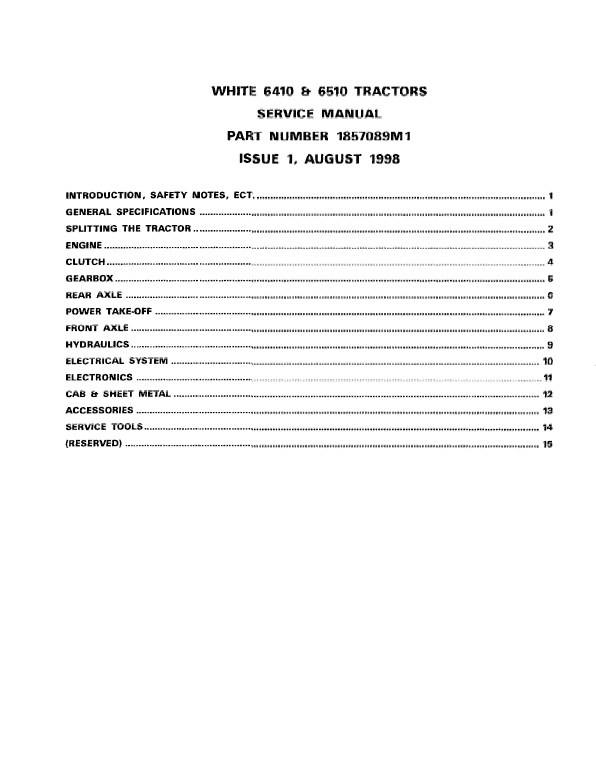

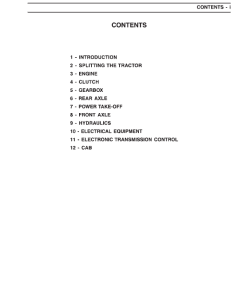

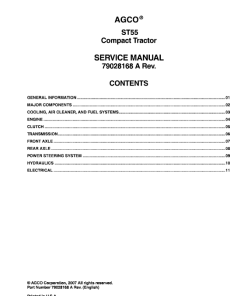

White 6410, 6510 Tractors Service Manual

$34.00

Length: 616 Pages

Format: PDF

Book Number: 1857089M1

Language: English

AGCO White 6410, 6510 Compact Tractor Manual

Product Overview

This comprehensive service manual for the AGCO White 6410 and 6510 compact tractors is an essential guide for owners and technicians. It is available in PDF format and consists of 616 detailed pages, providing extensive information necessary for maintaining and servicing these models.

Edition Details:

– Format: PDF

– Language: English

– Book Number: 1857089M1

Key Features

- Introduction to tractor safety and operational guidelines

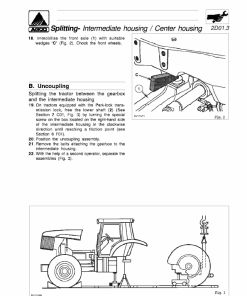

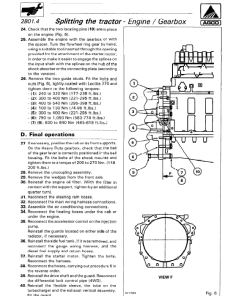

- Step-by-step procedures for splitting the tractor

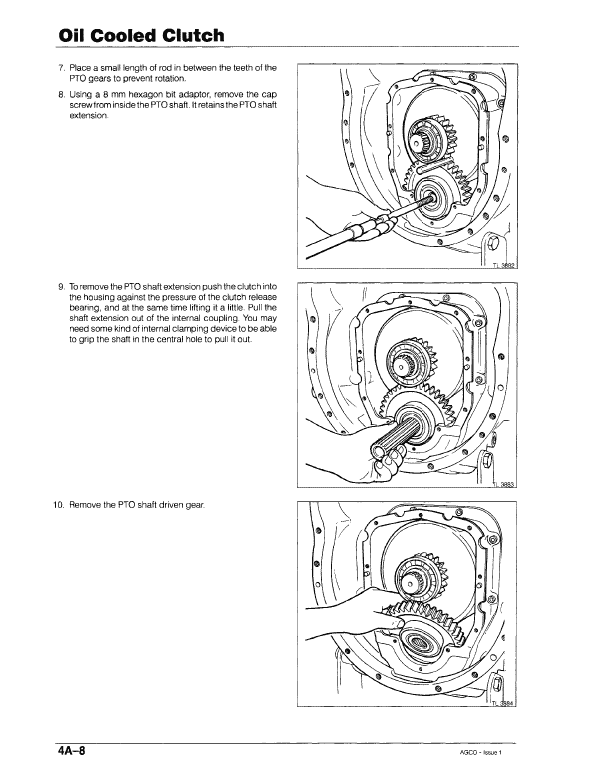

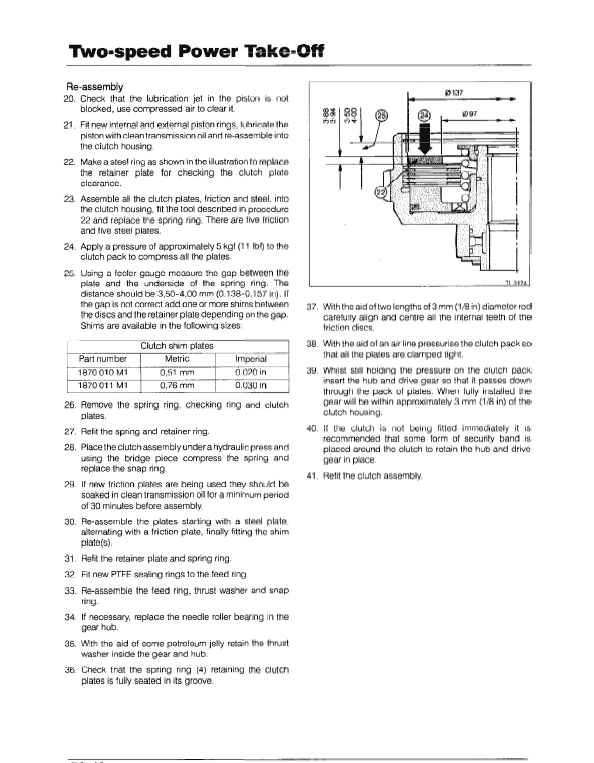

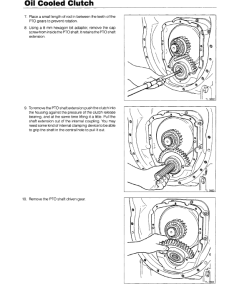

- Detailed engine and clutch repair instructions

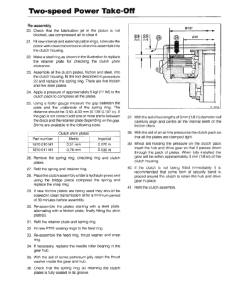

- Comprehensive gearbox maintenance guidelines

- Rear and front axle servicing information

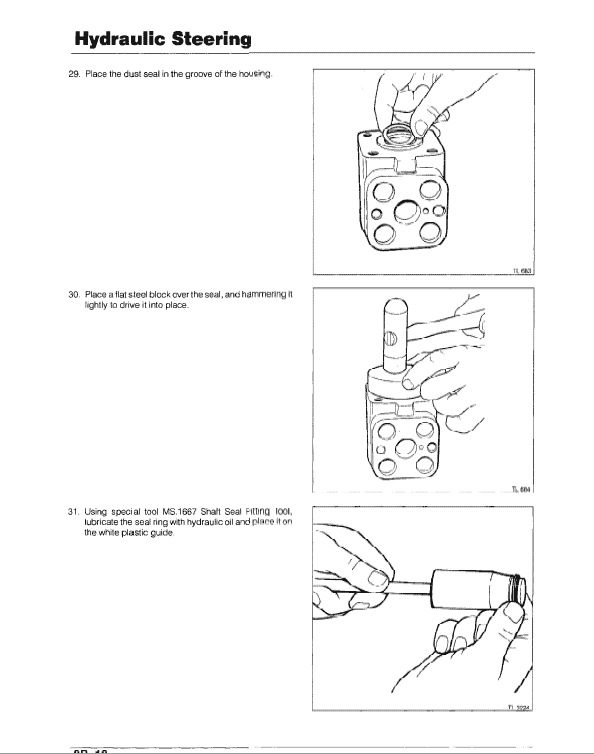

- Hydraulics system troubleshooting

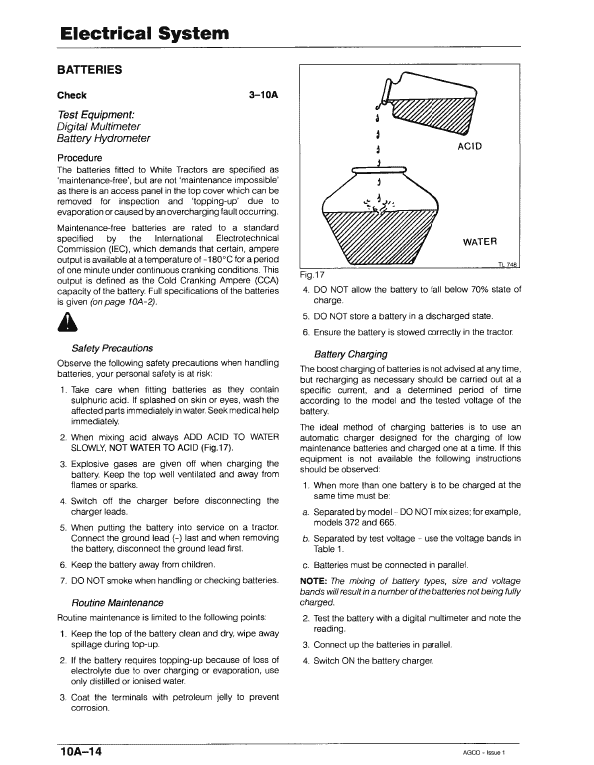

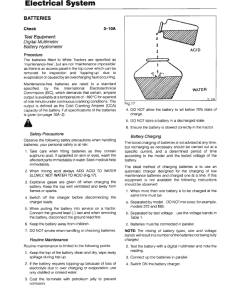

- Electrical and electronic system diagnostics

- Cab, sheet metal, and accessory maintenance tips

- Recommended service tools list

Benefits

- Helps ensure prolonged tractor lifespan through detailed maintenance procedures

- Increases efficiency and reduces downtime with clear troubleshooting steps

- Enhances safety by providing comprehensive operational guidelines

Usage Recommendations

- Ideal for DIY tractor owners and professional technicians alike

- Provides invaluable assistance for conducting regular maintenance and repairs

- Supports effective diagnosis of mechanical and electrical issues

White 6410, 6510 Manual Extract

Oil Supply Control Valve – Disassembly and Examination

The following are disassembly instructions for the oil supply control valve:

Dis-assembly Steps:

- Disconnect the two hydraulic hoses.

- Remove the clevis pin cylinder to operating lever.

- Remove the spring clip from the valve spindle pivot.

- Remove the cylinder assembly.

- Remove the circlip.

- Pull the valve assembly out of the cylinder.

- Remove and discard the ‘O’ ring in the cylinder body.

- Remove the crimped clip on the end of the spindle.

- Remove the valve components: valve, spring, washer, and spindle.

- Remove the internal ‘O’ ring and discard.

- Remove the wiper seal and discard.

Examination:

Clean all the components thoroughly and check for wear. Replace any worn parts. Ensure that the valve seat in the cylinder and on the spindle is in optimal condition. Verify that the valve slides freely up and down the valve spindle.

Only logged in customers who have purchased this product may leave a review.

SKODA FABIA IV (PJ) Repair Service Manual

SKODA FABIA IV (PJ) Repair Service Manual  SKODA OCTAVIA III (5E, NL, NR) Repair Service Manual

SKODA OCTAVIA III (5E, NL, NR) Repair Service Manual  SKODA KUSHAQ (PA) Repair Service Manual

SKODA KUSHAQ (PA) Repair Service Manual  Caterpillar CAT 3114 Engine Machine Service Repair Manual (97Z00001 and up)

Caterpillar CAT 3114 Engine Machine Service Repair Manual (97Z00001 and up)

Reviews

There are no reviews yet.