-

×

AGCO DT180A, DT200A, DT220A, DT240A Tractor Workshop Service Manual

$36.00

AGCO DT180A, DT200A, DT220A, DT240A Tractor Workshop Service Manual

$36.00 -

×

Gehl 521T Wheel Loader Operators and Parts Manual

$30.00

Gehl 521T Wheel Loader Operators and Parts Manual

$30.00 -

×

Gehl 721, 721T Wheel Loader Repair Service Manual

$32.00

Gehl 721, 721T Wheel Loader Repair Service Manual

$32.00 -

×

JCB Vibromax 405, 605, 606 Single Drum Roller Service Manual

$26.65

JCB Vibromax 405, 605, 606 Single Drum Roller Service Manual

$26.65 -

×

Gehl 480T Wheel Steer Loader Repair Service Manual

$33.00

Gehl 480T Wheel Steer Loader Repair Service Manual

$33.00 -

×

Gehl 680 Wheel Loader Repair Service Manual

$33.00

Gehl 680 Wheel Loader Repair Service Manual

$33.00 -

×

Manitou MHT 7140, MHT 10160, MHT 10210L M Series Telehandler Repair Manual

$31.00

Manitou MHT 7140, MHT 10160, MHT 10210L M Series Telehandler Repair Manual

$31.00 -

×

JCB Vibromax 1103 Single Drum Roller Service Manual

$26.50

JCB Vibromax 1103 Single Drum Roller Service Manual

$26.50 -

×

AGCO LT75, LT85, LT90, LT95 Tractor Workshop Repair Manual

$37.00

AGCO LT75, LT85, LT90, LT95 Tractor Workshop Repair Manual

$37.00 -

×

Manitou MHT 10120 L, MHT 10160 L Telehandler Repair Manual

$38.00

Manitou MHT 10120 L, MHT 10160 L Telehandler Repair Manual

$38.00 -

×

JCB 520-50, 525-50 Year 1996 - 2012 Loadall Service Manual

$33.00

JCB 520-50, 525-50 Year 1996 - 2012 Loadall Service Manual

$33.00

Willmar 4560 Wrangler Loader Service Manual

$35.00

Comprehensive Coverage: The service manual spans 543 pages and includes a detailed parts catalog with 184 pages.

Format: PDF

Book Numbers: 79033462 & AG334846

Language: English

SKU: 426978

Category: AGCO

AGCO Willmar 4565 Wrangler Loader Manual

Product Overview

The AGCO Willmar 4565 Wrangler Loader Manual is an essential guide for owners and operators of the Willmar 4560 Loader. This comprehensive manual provides detailed insights into the operation, maintenance, and parts of your loader in a user-friendly PDF format. With a total of 543 pages in the service manual and an additional 184 pages in the parts catalog, it is an indispensable resource for ensuring the optimal performance and longevity of your machine.

Key Features

- Format: PDF

- Book Numbers: 79033462 & AG334846

- Language: English

- Extensive Coverage: 543 pages of detailed service instructions

- Comprehensive Parts Catalog: 184 pages of part listings and diagrams

Benefits

- Comprehensive Understanding: Gain a thorough understanding of the loaderu2019s systems, including hydraulic and electrical.

- Enhanced Maintenance Capability: Perform routine maintenance and troubleshoot with ease using detailed instructions.

- Efficient Operation: Maximize performance by following precise operational guidelines.

Usage Recommendations

- Refer to the manual regularly for maintenance schedules and procedures.

- Use the parts catalog to identify and order correct components for repairs.

- Follow step-by-step instructions for troubleshooting common issues.

Manual Table of Contents

This manual includes sections on:

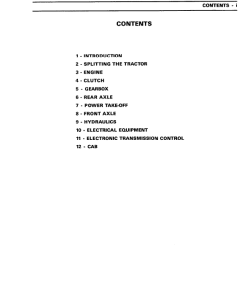

- Introduction

- Engine

- Frame

- Steering System

- Hydraulic System

- Electrical System

- Cab

- HVAC

- Accessories

- Attachments

Willmar 4560 Manual Extract

The drive system of the Willmar 4560 Loader begins with a shuttle-shifted hydrostatic transmission featuring IPOR technology. This transmission allows for variable displacement, modulating oil flow from minimum to maximum. Machine speed is easily regulated through a foot pedal.

The forward and reverse motion is managed via a shift lever on the steering column, which communicates through an electrical signal to the transmission’s directional controller. The drive pedal applies control pressure via the hydro’s Ps-port, enabling speed regulation.

Pushing the pedal down opens the spool, permitting controlled pressure oil into the stroking piston, thereby increasing pressure and oil flow to the wheel motors for faster movement. When the pedal is released, pressure to the controller is halted, resetting the stroking piston to neutral and returning oil to the R-port atop the hydro.

The hydro system includes a charge pump providing essential oil flow and pressure for operation. This charge pressure is adjustable to meet manufacturer specifications, with the charge pressure relief valve preset to 2200 kPa (319 psi).

Only logged in customers who have purchased this product may leave a review.

Related products

$26.00

$34.00

$35.00

$34.00

$36.00

$27.50

Reviews

There are no reviews yet.