Takeuchi TB020 Compact Excavator Service Manual

Product Overview

The Takeuchi TB020 Compact Excavator Service Manual is an essential guide for anyone involved in the maintenance and repair of the TB020 model. This comprehensive manual covers the operation, service, repair, and maintenance of your excavator, along with detailed safety instructions to ensure safe and effective use.

Manual Details:

- Format: PDF

- Language: English

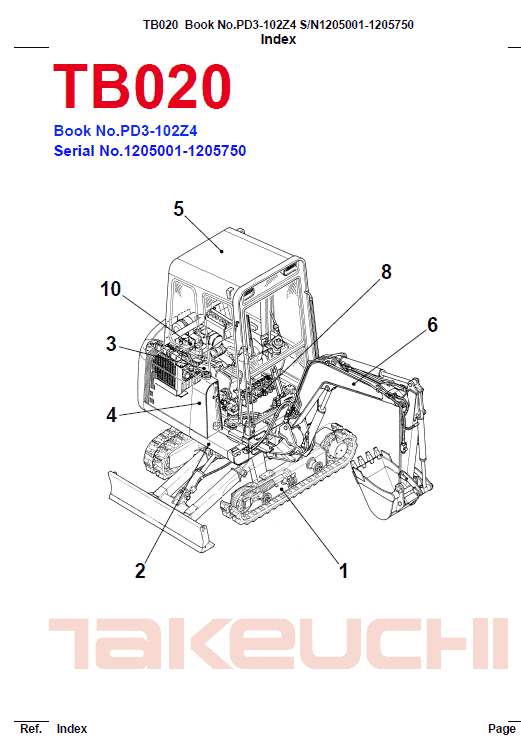

- Serial Number Range: 1205001-1205750

- Total Pages:

- Service Manual: 490 pages

- Operating Manual: 82 pages

- Parts Manual: 237 pages

Key Features

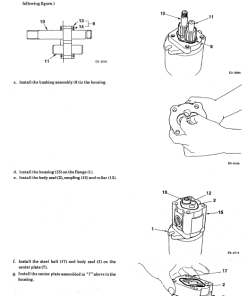

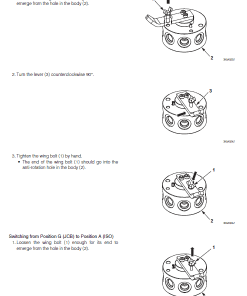

- Comprehensive procedures for disassembly and reassembly of the machine.

- Maintenance procedures and reference values.

- Troubleshooting guidelines.

- Outline specifications.

- Safety and operation instructions.

Benefits

- Enhance maintenance techniques with detailed guidance.

- Ensure the machine’s longevity and reliability.

- Empower maintenance personnel with clear instructions and reference materials.

Usage Recommendations

- Consistently refer to this manual for improved service activities.

- Store the manual close to the excavator for easy access.

- Provide this manual to the new owner when transferring ownership.

- Regularly perform inspections and rectifications for any machine irregularities.

- Closely follow shutdown procedures when experiencing a breakdown.

Additional Information

Note that the contents and diagrams in this manual are subject to change and may not match your specific machine due to design modifications. Always ensure that the manual is the correct version for your excavator model.

Table of Contents

I. GENERAL

II. SPECIFICATIONS

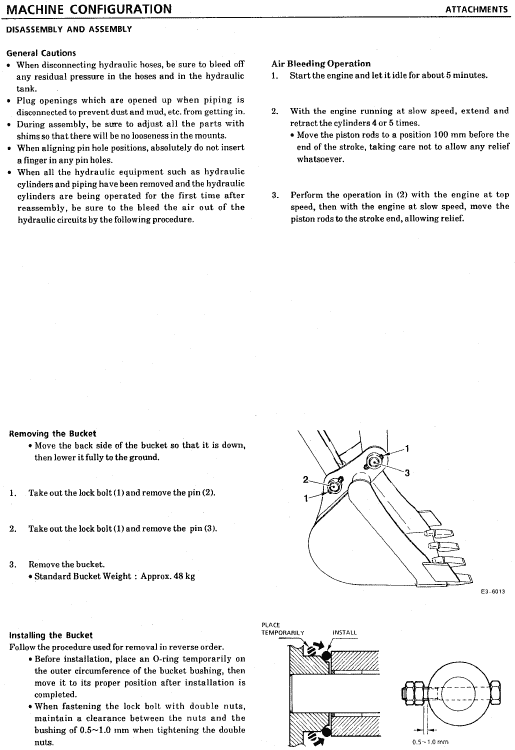

III. MACHINE CONFIGURATION

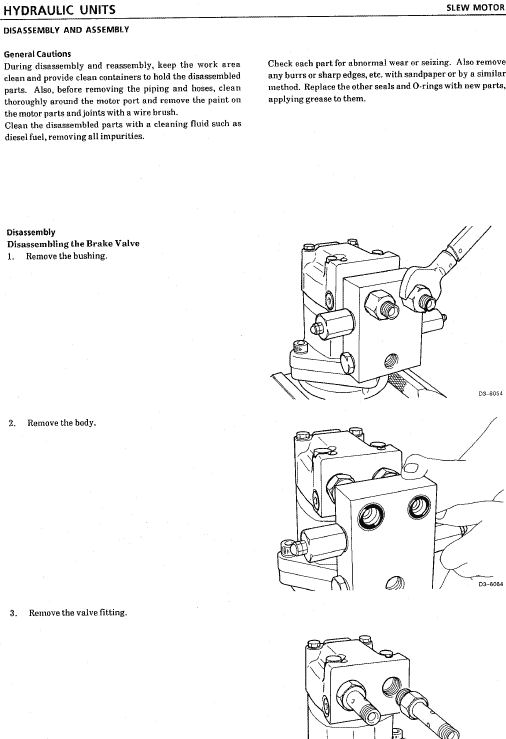

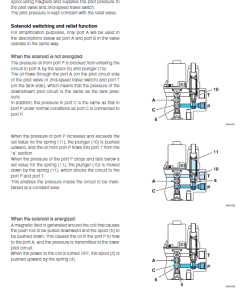

IV. HYDRAULIC UNITS

V. TROUBLESHOOTING

VI. ENGINE

Extract from the Service Manual

Before operating the Takeuchi TB020, perform the prescribed inspections and make necessary repairs immediately upon discovering any irregularities. If a critical failure occurs, such as a loss of steering, service brakes, or engine control, stop the machine quickly, follow the shutdown procedure, and secure the vehicle until repairs are completed.

/p>

Maintenance Procedure Example:

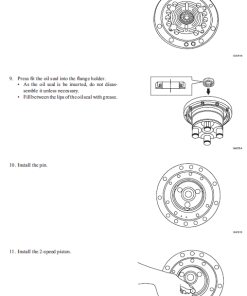

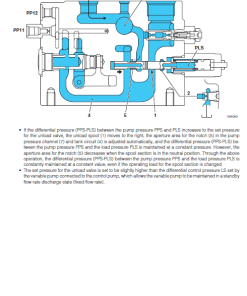

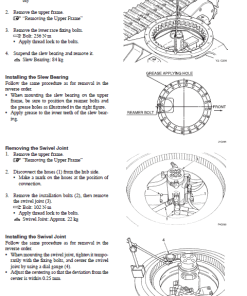

- Connect a pipe from the hydraulic pump to the shaft side port.

- Attach a pressure gauge to the hub side.

- Gradually increase the pressure to 210 kg/cm2 while adjusting the relief valve, then conduct a 1-minute leak test.

- Release ports on both sides and visually check for leakage.

- Perform an external leakage check using a color test.

Only logged in customers who have purchased this product may leave a review.

Reviews

There are no reviews yet.