Takeuchi TL250 Compact Loader Service Manual

Product Overview

The Takeuchi TL250 Loader service manual is an essential guide for operating, servicing, repairing, and maintaining your compact loader. The manual is available in English and French, ensuring accessibility for a wider audience. It comprises several detailed sections including the Service Manual (548 pages), Operators Manual (213 pages), Parts Manual (451 pages), and the Engine Manual for V3800DI-T-E3B-TLTU-1 (KUBOTA) spanning 106 pages. This extensive documentation covers all applicable serial numbers for the TL250 model.

Designed for maintenance professionals, this manual provides step-by-step instructions for disassembling and reassembling the machine, along with comprehensive maintenance procedures, reference values, troubleshooting techniques, and specification details. Please utilize this manual as a reference to enhance your maintenance operations. Note that due to ongoing design modifications, the contents and diagrams may not exactly match every machine model.

We recommend keeping the manual close at hand, preferably attached to the machine. It should also be passed on to future owners to ensure continuity of care.

Key Features

- In-depth operational guidance and service instructions.

- Multi-language support: English and French.

- Covers a comprehensive range of pages for different manual types.

- Applicable for all TL250 serial numbers.

Benefits

- Facilitates efficient and effective maintenance practices.

- Enhances troubleshooting and repair skills for maintenance personnel.

- Ensures safety and reliable operation of the loader.

- Extends the lifecycle of the equipment through proper maintenance.

Usage Recommendations

- Perform prescribed inspections before operation and attend to repairs promptly if irregularities are found.

- If experiencing control failures such as steering or brakes, stop the machine promptly and secure it until repairs are complete.

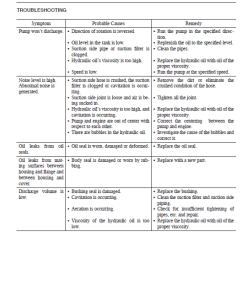

- Review the troubleshooting section for common issues and their solutions.

Table of Contents of TL250 Instructions Manual:

I. GENERAL

II. SPECIFICATIONS

III. MACHINE CONFIGURATION

IV. HYDRAULIC UNITS

V. TROUBLESHOOTING

VI. ENGINE

Extract from the Service Manual:

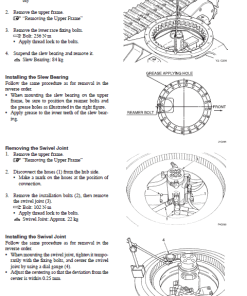

1. Check the load check valve on the control valve.

a. Disconnect the hose connecting the control valve and the arm cylinder from the control valve.

b. Connect the hose just disconnected to the bucket block.

c. Move the lever (bucket) to operate the arm cylinder.

If the arm cylinder operates normally, the load check valve is likely faulty. It’s important to lower the lift arm and position the bucket on the ground before beginning.

An issue with the load check valve might cause temporary reverse oil flow leading to a drop in the lift arm due to load pressure.

2. Check for leaks inside the arm cylinder.

Leaks can cause oil to move from the head side (A) to the rod side (B), which results in a drop of the lift arm due to low pressure and flow rate at spool initiation. This indicates insufficient drive power and a need for cylinder inspection.

Only logged in customers who have purchased this product may leave a review.

Reviews

There are no reviews yet.