Takeuchi TW50 Wheel Loader Service Manual

$33.50

Comprehensive Service and Repair Guides

Enhance your understanding and maintenance of the Takeuchi TW50 with this extensive manual collection. This set includes:

Takeuchi TW50 Wheel Loader Service Manual

Product Overview

The Takeuchi TW50 Wheel Loader Service Manual is an essential resource for operators and technicians involved in the maintenance and repair of the Takeuchi TW50 Loader. This comprehensive guide is available in PDF format and is written in English. It consists of multiple manuals including the Service Manual (242 pages), Operators Manual (84 pages), Parts Manual (115 pages), and the Engine Manual specifically for the HP818485U model (132 pages).

Suitable for all applicable Serial Numbers (S/N), this manual provides detailed instructions on operation, service, repair, and maintenance procedures, along with crucial safety guidelines to ensure safe and efficient usage of the loader.

Key Features

- Detailed service instructions spanning 242 pages covering various operational aspects.

- Comprehensive operator guidance across 84 pages for safe and effective handling.

- Parts manual offering 115 pages of detailed component information.

- 132-page engine manual dedicated to the HP818485U model.

- In-depth troubleshooting processes and maintenance reference values.

Benefits

- Improves maintenance techniques by offering clear procedures for disassembly and reassembly.

- Enhances safety with structured safety instructions and operational guidelines.

- Facilitates effective problem-solving through detailed troubleshooting sections.

- Helps maintain optimal machine performance by adhering to recommended service procedures.

Usage Recommendations

- Always store the manual in a convenient location, ideally on the machine itself.

- Transfer the manual to the new owner when selling the machinery.

- Perform prescribed inspections before operating the loader.

- Address any detected irregularities immediately to avoid equipment failure.

- In case of critical failures such as steering or engine issues, halt operations promptly and secure the machine until the issue is resolved.

Table of Content of TW50 Instructions Manual

The TW50 Instructions Manual is systematically organized into the following sections:

- I. General

- II. Specifications

- III. Machine Configuration

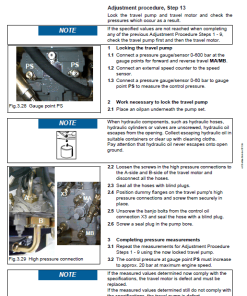

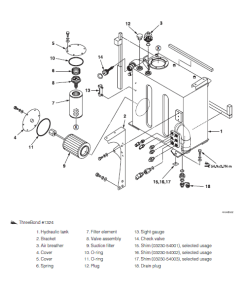

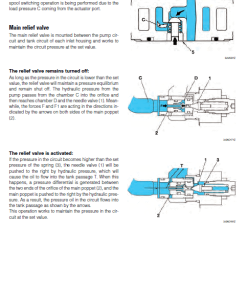

- IV. Hydraulic Units

- V. Troubleshooting

- VI. Engine

Service Extract: Replacing the Hoisting Gear Components

n

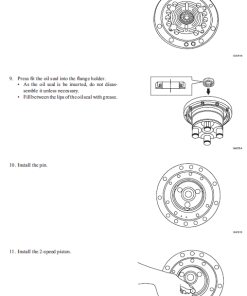

Replacing the Bearing Bolts:

- Unscrew any locking screws (1.1) on the bearing bolts.

- Use a hydraulic press to remove remaining bearing bolts (1).

- Support heavy components with a crane or hoisting system.

- Thoroughly clean the removed bearing bolts and bushes.

- Inspect the bearing bushes (2) for damage.

Replacing the Bearing Bushes:

- Remove retaining rings if present to extract bearing bushes.

- Press out old bushings and clean the bearings thoroughly.

- Install new bushes, ensuring correct alignment of grease holes.

- Reinsert retaining rings and apply grease to the new bushes.

- Reassemble the components and ensure proper alignment of bolts.

- Secure with new locking screws.

Only logged in customers who have purchased this product may leave a review.

Reviews

There are no reviews yet.