Toyota 8FGU15, 8FGU18, 8FGU20, 8FGU25, 8FGU30, 8FGU32 Forklift Repair Manual

$45.00

Language: English

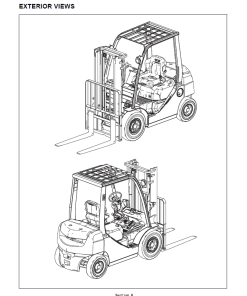

Models Covered: 8FGU15, 8FGU18, 8FGU20, 8FGU25, 8FGU30, 8FGU32

TOYOTA Forklift Repair Manual for Models 8FGU15 to 8FGU32

Product Overview

This comprehensive TOYOTA Forklift Repair Manual covers the models 8FGU15, 8FGU18, 8FGU20, 8FGU25, 8FGU30, and 8FGU32. Delivered in a convenient PDF format, this manual is an essential resource for the effective servicing and maintenance of these forklift models. The content is in English and includes all necessary information to ensure quick and accurate repairs.

Key Features

- Extensive repair manual with 1389 pages for the specified forklift models.

- Supplement Manual covering updates as of April 2010, consisting of 227 pages.

- Detailed Parts Catalog with a total of 166 pages.

- Comprehensive 4Y Model Engine Manual with 250 pages.

- 4Y-E Engine Manual providing detailed insights, covering 104 pages.

Benefits

- Facilitates precise and efficient servicing of the Toyota 8FGU Forklift series.

- Includes updates and revisions post-April 2010 to ensure current information.

- Helps identify discrepancies due to design changes and provides timely updates.

- Serves as a guide alongside mounted engine repair manuals for comprehensive understanding.

Usage Recommendations

- Prepare all necessary tools and measuring instruments like circuit testers and oil pressure gauges before working.

- Always verify cable colors and wiring states before disconnection.

- Meticulously organize disassembled parts to prevent confusion during reassembly.

- Use clean tools and operate in clean environments when inspecting precision parts like control valves.

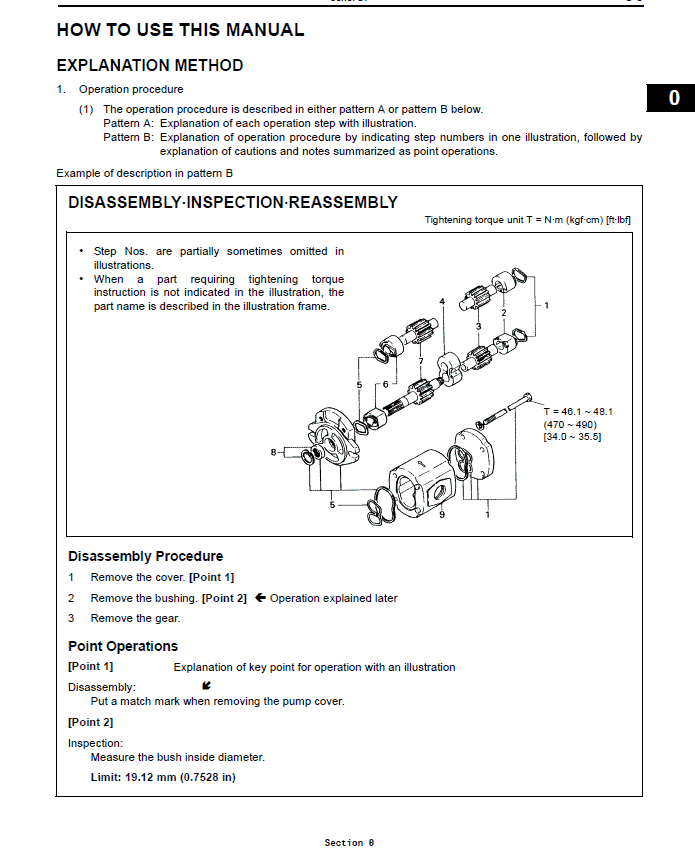

- Adhere strictly to specified procedures for disassembly, inspection, and reassembly.

- Replace gaskets, packings, and O-rings to maintain function and integrity.

- Use genuine Toyota parts and follow specified torque settings for replacements.

Table of Contents

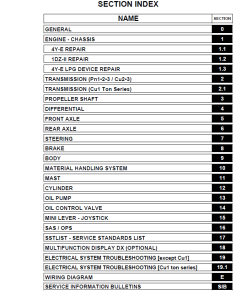

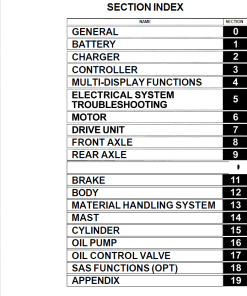

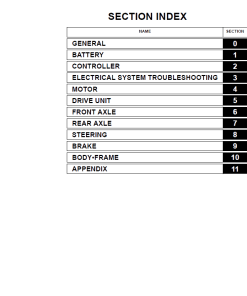

The manual includes comprehensive sections on:

- General Repair Guidelines

- Engine and Chassis

- 4Y-E and 1DZ-II Engine Repairs

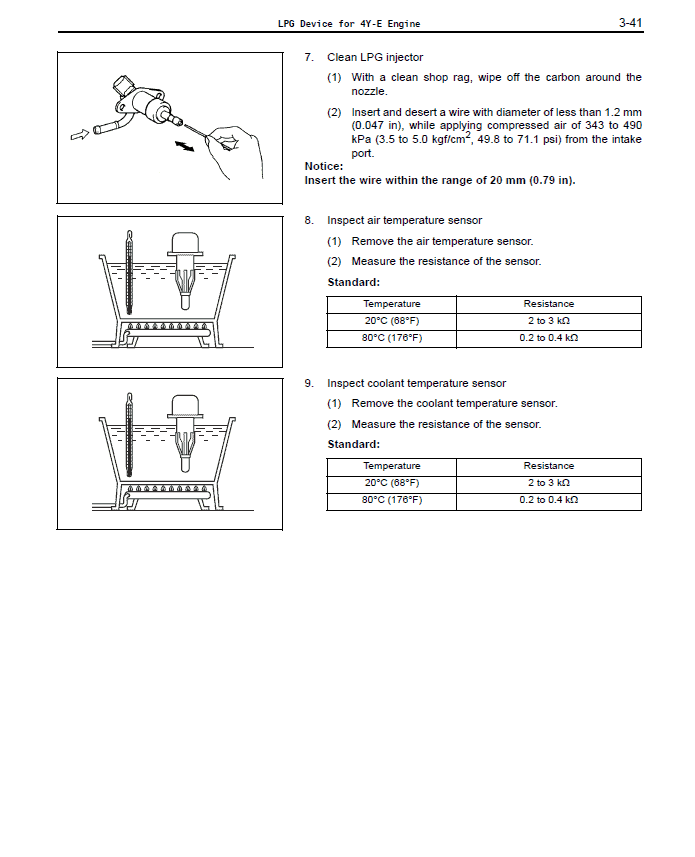

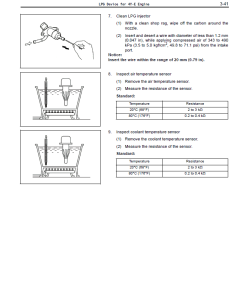

- LPG Device Repair

- Transmission, Propeller Shaft, and Differential Maintenance

- Axle, Steering, and Brake Systems

- Body and Material Handling System

- Mast, Cylinder, and Oil Pump Repair

- Oil Control Valve and Mini Lever Joystick

- SAS/OPS Systems

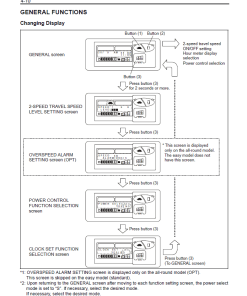

- Service Standards List and Multifunction Display (Optional)

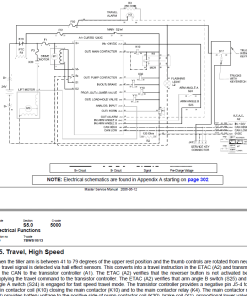

- Electrical System Troubleshooting and Wiring Diagrams

- Service Information Bulletins

Operational Tips

Here are some key operational tips:

- Adequately prepare by setting up all required tools and measurement instruments before beginning work.

- Careful examination and verification of wiring are essential before any disconnection.

- Organization during disassembly can prevent misplacement and ensures a smoother reassembly process.

- When handling precision components, use appropriate tools and ensure cleanliness to avoid damage.

- It’s crucial to follow the specified disassembly, inspection, and reassembly procedures.

- Always use new gaskets, packings, and O-rings each time a component is disassembled.

- Adherence to the specified tightening torque is necessary for all bolts and nuts.

Only logged in customers who have purchased this product may leave a review.

Related products

Toyota Forklift

Toyota 8FGCU15, 8FGCU18, 8FGCU20, 8FGCU25, 8FGCU30, 8FGCU32, 8FGCSU20 Forklift Repair Manual

Toyota Forklift

Toyota 7BWS10, 7BWS13 Lift Pallet Truck Service Repair Manual

Toyota Forklift

Toyota Forklift

Toyota Forklift

Toyota CBT4, CBTY4, CBT6 Towing Tractor Repair Service Manual

Reviews

There are no reviews yet.