Volvo A30C BM Articulated Dump Truck Repair Service Manual

$35.00

Volvo A20 6×4 BM Articulated Dump Truck Repair Service Manual

Explore the comprehensive Repair Service Manual for the Volvo A20 6×4 BM Articulated Dump Truck. This detailed PDF manual contains 301 pages of valuable information for maintenance and repair.

Table of Contents: A30C BM Service Information

Product Overview

This comprehensive guide provides detailed service information for the A30C BM. It includes instructions and specifications necessary for maintenance, compliance, and troubleshooting of this machinery. The document is structured to cover every aspect of the A30C BM, ensuring all technical and safety information is readily accessible for optimized machine performance.

Key Features

- General Overview: Detailed description and specifications of the complete machine.

- Standard Parts & Service: Information on standard parts used, emphasizing safety and service procedures, particularly in sections 171-179. View service instructions.

- Engine & Equipment: Focused on engine installation, components such as cylinder liners, pistons, and valve mechanisms, and specific parts like the crankshaft and flywheel.

- Lubricating System: Includes details like the oil cooler and other components (sections 221-224).

- Fuel System: Comprehensive information on components such as the fuel pump, tank, injectors, and control systems (sections 233-238).

- Cooling System: Covers details on the coolant pump, thermostat, and fan components (sections 261-269).

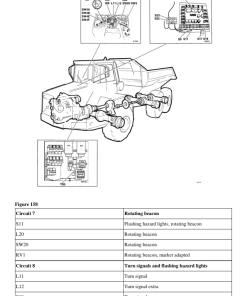

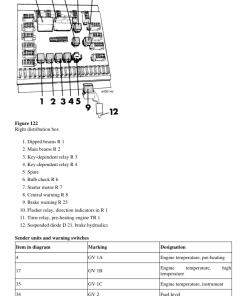

- Electrical Systems: Covers the electrical, warning, and information systems including battery and alternator components.

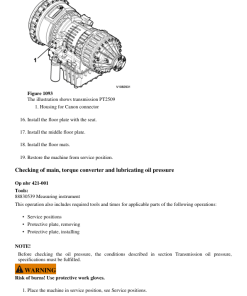

- Transmission & Powertrain: In-depth information about power transmission, including torque converters and hydraulic controls. Check sender unit resistance.

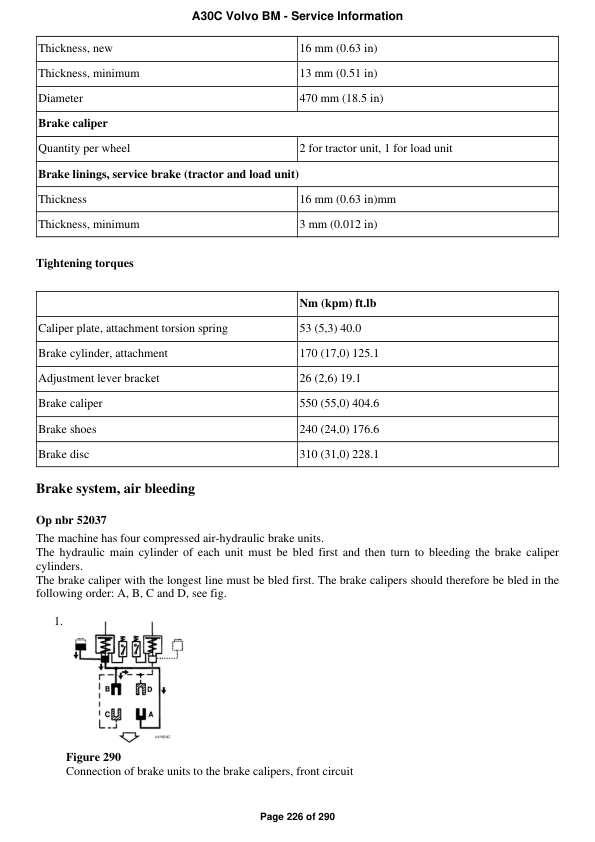

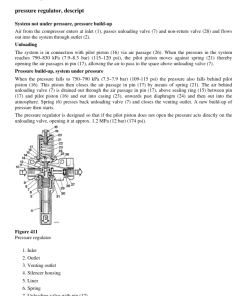

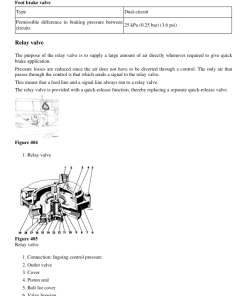

- Braking Systems: Comprehensive coverage of brake systems, including wheel, parking, and compressed-air brakes.

- Steering: Includes detailed information on the steering systems, steering gear, and hydraulic equipment. Check hydraulic pressure.

- Frame & Suspension: Information on the frame, axle suspension, and related components, including wheels and track units.

- Machinery House & Exterior Parts: Details on the engine hood and cab-related components.

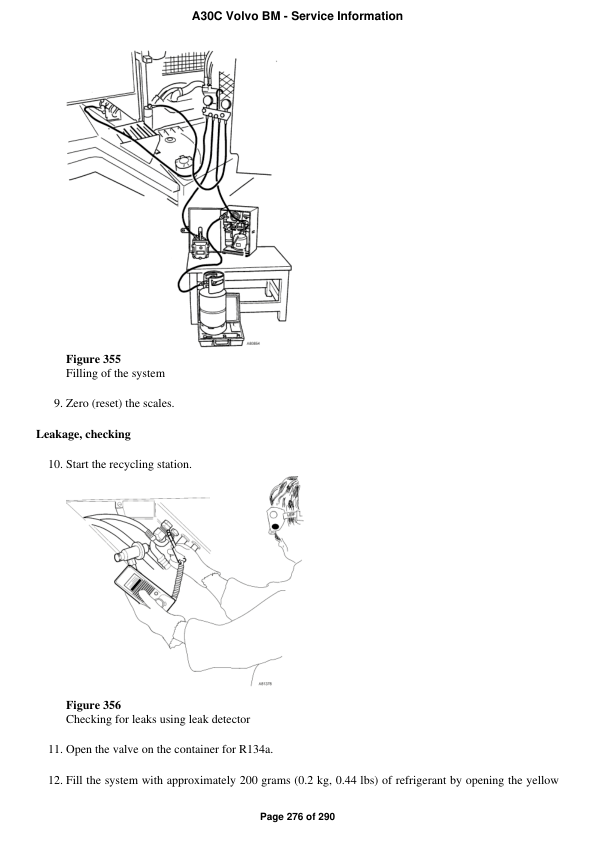

- Hydraulic & Miscellaneous Equipment: Covers working and servo hydraulics, and load carrying equipment such as haulers and tipping systems. Check hydraulic pump leakage.

Benefits

- Comprehensive Guidance: Enables thorough understanding and efficient maintenance of the machine.

- Enhanced Safety: Emphasizes critical safety protocols to protect operators and machinery.

- Optimized Performance: Regular maintenance insights facilitate sustained performance and reliability.

Usage Recommendations

- Regularly refer to the standard parts and service section to ensure compliance with maintenance schedules.

- Utilize the lubricating and cooling systems information to prevent overheating and reduce wear.

- Follow safety steps outlined in the electrical systems to prevent operational hazards.

- Utilize the provided service links for specific troubleshooting guidance on common issues.

Only logged in customers who have purchased this product may leave a review.

Related products

Articulated Dump Truck

Volvo A25 6×4 BM Articulated Dump Truck Repair Service Manual

Articulated Dump Truck

Volvo A25C 4×4 BM Articulated Dump Truck Repair Service Manual

Articulated Dump Truck

Volvo A25 4×4 BM Articulated Dump Truck Repair Service Manual

Articulated Dump Truck

Volvo A25B 4×4 BM Articulated Dump Truck Repair Service Manual

Articulated Dump Truck

Articulated Dump Truck

Articulated Dump Truck

Articulated Dump Truck

Reviews

There are no reviews yet.