EC480E LR Service Information

Product Overview

The EC480E LR is a heavy-duty construction machine designed for efficiency and reliability. This service information provides detailed coverage of various components and systems critical for maintenance, operation, and safety standards. It includes comprehensive descriptions spanning the engine, electrical systems, hydraulic systems, and more, ensuring the effective functioning of all machine parts.

Key Features

- Engine: Detailed installation and functionality overview with additional information on the cylinder block, crankshaft, and oil sump.

- Lubricating System: Covers vital parts such as the oil pump, cooler, and connections.

- Fuel System: Information about the fuel pump, injector, filters, and comprehensive fuel management.

- Inlet and Exhaust Systems: Includes details on silencers, catalytic converters, turbochargers, and emission control equipment.

- Cooling System: Encompasses radiators, fan assemblies, and cooling connections.

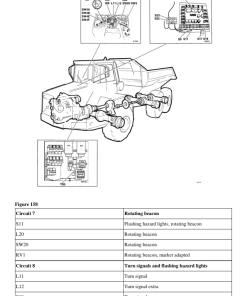

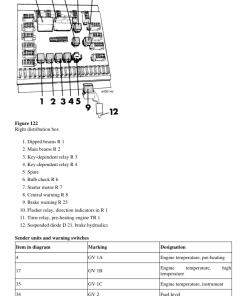

- Electrical System: Offers insights into battery storage, alternators, warning systems, and informational systems to maintain operational safety.

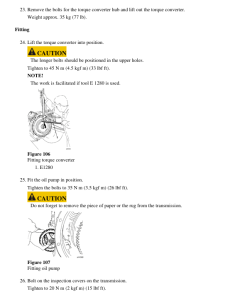

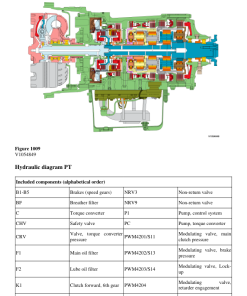

- Power Transmission: General information on gearboxes and drive mechanisms, integral for maintaining drivetrain integrity.

- Frame and Suspension: Covers all aspects of the machine framework, suspension components, and track/wheel units for stability and support.

- Hydraulic System: Details the workings of hydraulic machinery, including pumps, valves, and servo mechanisms for effective operation.

- Cab and Interior: Information on seating, upholstery, air conditioning systems, and integrated controls for operator comfort and efficiency.

Benefits

- Enhanced Safety: Built-in safety features and instructions ensure a secure work environment.

- Efficient Maintenance: Comprehensive specifications and standard parts guide simplify maintenance tasks.

- Operational Reliability: High-quality components and systems designed for long-term durability and performance.

- Versatility: Suitable for a wide range of construction and industrial applications due to its robust design and comprehensive system integration.

Usage Recommendations

- Regular Inspections: Perform routine maintenance checks and inspections to keep the machine in top working condition.

- Adequate Training: Ensure operators are well-trained in safety protocols and machine operations.

- Proper Lubrication: Follow the lubrication guidelines to maintain optimal performance of moving parts.

- Use Genuine Parts: Utilize specified lubricants, fuels, and parts for repairs and replacements to ensure compatibility and efficiency.

- Monitor System Alerts: Pay attention to warning systems and fault-tracing measures to prevent potential malfunctions.

Only logged in customers who have purchased this product may leave a review.

Related products

Articulated Dump Truck

Volvo A20 6×4 BM Articulated Dump Truck Repair Service Manual

Articulated Dump Truck

Articulated Dump Truck

Articulated Dump Truck

Articulated Dump Truck

Volvo A30F Articulated Dump Truck Repair Service Manual (SN 12001-99999)

Articulated Dump Truck

Articulated Dump Truck

Volvo A25C 4×4 BM Articulated Dump Truck Repair Service Manual

Articulated Dump Truck

Reviews

There are no reviews yet.