Volvo SD200 Soil Compactor Repair Service Manual

$36.00

Volvo A20 6×4 BM Articulated Dump Truck Repair Service Manual

Enhance your Volvo A20 6×4 BM Articulated Dump Truck maintenance with this detailed Repair Service Manual.

SD200 Service Information

Product Overview

The SD200 Service manual provides comprehensive guidelines and specifications necessary for the efficient operation and maintenance of the SD200 machine. This document includes essential information on transportation, storage, and operating protocols, ensuring optimal performance and longevity. Designed for both seasoned technicians and new operators, the guide emphasizes safety and precision in every aspect of equipment handling.

Key Features

- General Specifications: Detailed mechanical and operational specifications of the SD200.

- Transport, Storage, and Operating Instructions: Step-by-step guidelines for handling and maintaining the equipment.

- Standard Time and Tools: Time estimations and tool recommendations for various service tasks.

- Standard Parts and Service: Information on lubricants, fuel, and other fluids essential for maintenance.

- Engine and Mounting Equipment: Comprehensive details on engine installation and its functions.

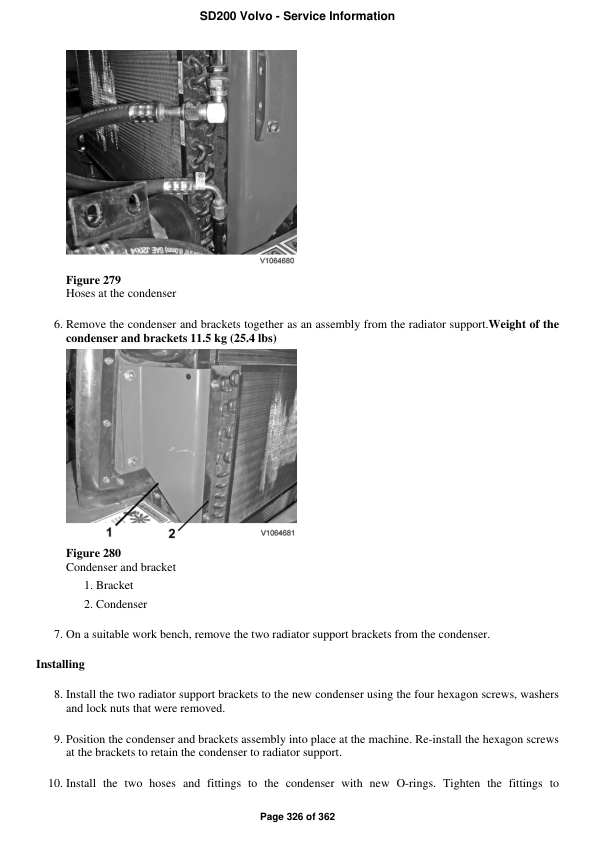

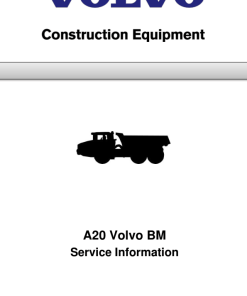

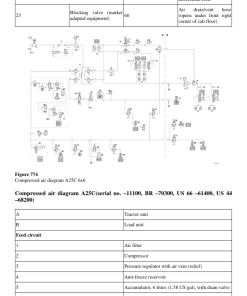

- Fuel and Cooling Systems: Insights into the fuel system components and cooling mechanisms.

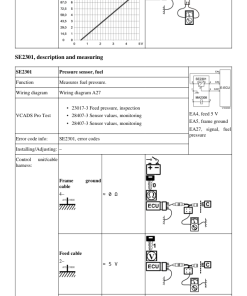

- Electrical Systems: Information on batteries, starting systems, and other electrical components.

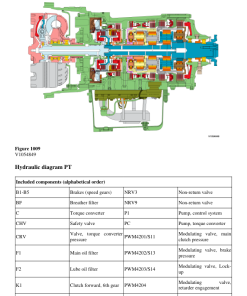

- Power Transmission and Brake Systems: Descriptive overview and functional details of the power transmission and brake systems.

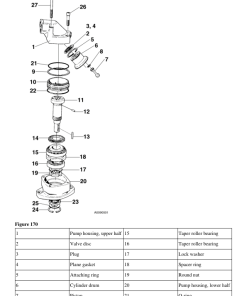

- Steering and Wheel Assemblies: Detailed description of steering mechanisms and wheel components.

- Machinery Housing and Interior: Insights into the cabin, engine hoods, and interior trimming for safety and comfort.

- Hydraulic Systems: Detailed information on hydraulic equipment for digging, handling, and grading.

Benefits

- Improved Operation Safety: Ensures all safety protocols are adhered to, reducing risks during operations.

- Optimized Performance: Detailed maintenance schedules and procedures enhance equipment efficiency and durability.

- Cost-Effective Maintenance: Comprehensive parts and tools list streamlines repair processes and reduces costs.

Usage Recommendations

- Regular Inspections: Perform detailed arrival and delivery inspections to maintain optimum functionality.

- Scheduled Maintenance: Follow specified maintenance schedules for essential components like engines and hydraulic systems.

- Emergency Readiness: Familiarize yourself with emergency measures for quick response during unexpected breakdowns.

Only logged in customers who have purchased this product may leave a review.

Related products

Articulated Dump Truck

Articulated Dump Truck

Articulated Dump Truck

Articulated Dump Truck

Articulated Dump Truck

Articulated Dump Truck

Articulated Dump Truck

Articulated Dump Truck

Volvo A25F Articulated Dump Truck Repair Service Manual (SN after 320001 -)

Reviews

There are no reviews yet.