Yale ERP16AAF, ERC16AAF, ERP18AAF, ERC18AAF, ERP20AAF, ERC20AAF Forklift B814 Service Repair Manual

$35.00

Yale Forklift Service Repair Manual

Access the comprehensive Yale Forklift Service Repair Manual for models ERP16AAF, ERC16AAF, ERP18AAF, ERC18AAF, ERP20AAF, and ERC20AAF. Designed to assist with repair and maintenance tasks, this manual is an essential resource for these forklift models.

Details:

Yale ERP and ERC Forklift Service Repair Manual for Models B814

Product Overview

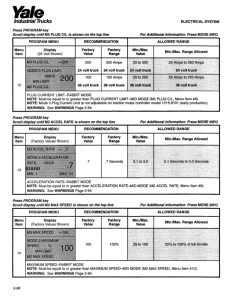

Enhance your understanding and maintenance of Yale forklifts with the comprehensive Yale ERP16AAF, ERC16AAF, ERP18AAF, ERC18AAF, ERP20AAF, ERC20AAF Forklift B814 Service Repair Manual. This manual, conveniently formatted in PDF and presented in English, includes detailed instructions, diagrams, and troubleshooting steps over a span of 1110 pages, ensuring you have all the necessary information to effectively maintain and repair these models.

Key Features

- Extensive 1110-page coverage of Yale forklift models.

- In-depth technical specifications and service procedures.

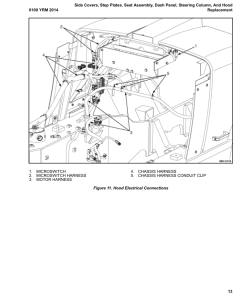

- Includes electrical diagrams and maintenance protocol.

- Written in English, available in PDF format.

Benefits

- Comprehensive Guide: Covers all essential aspects of maintenance and repair.

- Enhanced Performance: Provides detailed maintenance steps to ensure optimal forklift performance.

- Cost-Effective: Reduces the need for external technician services by empowering in-house maintenance.

Usage Recommendations

- Ideal for technicians and maintenance personnel in charge of Yale forklifts.

- Essential for troubleshooting and repairs to minimize downtime.

- Recommended for users seeking detailed specifications and operational insights.

Table of Contents

- Tilt Cylinders All Models Except

- Metric and Inch (SAE) Fasteners

- DC Motor Maintenance All Electric Lift Trucks

- Industrial Battery

- Steering Housing and Control Unit

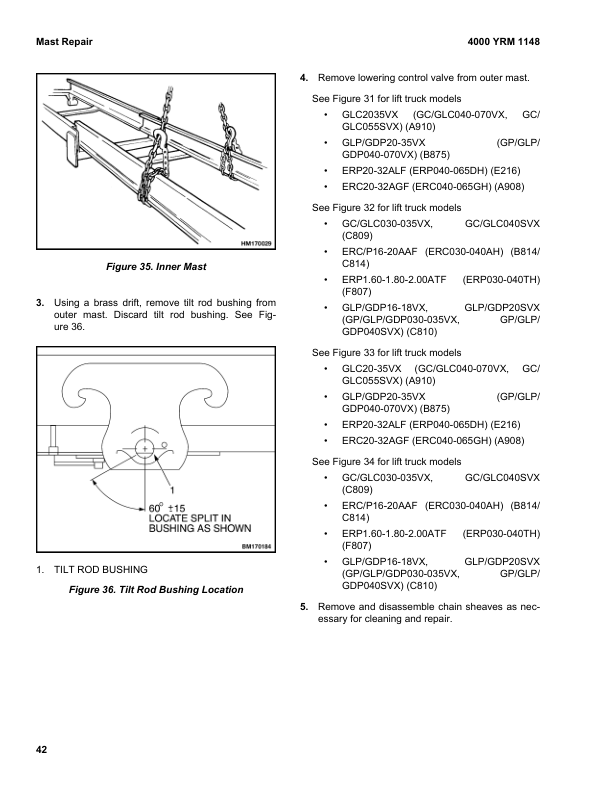

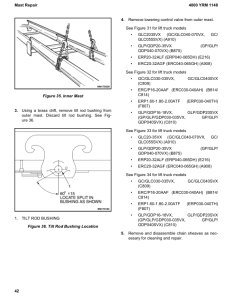

- Mast D and Mast Repairs

- Frame

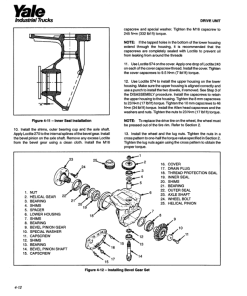

- Drive Axle, Speed Reducer, and Differential

- Steering Axle

- Brake System

- Hydraulic System

- Manual Hydraulic Control Valve

- Steering System for AC Electric Lift Trucks

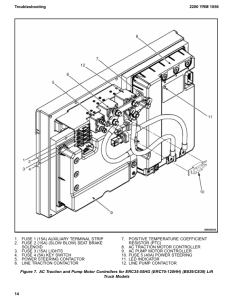

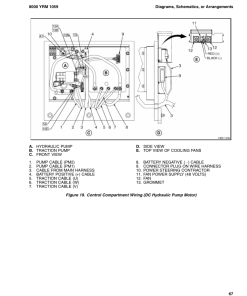

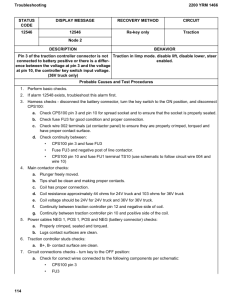

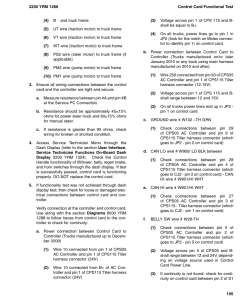

- Electrical System (Trucks with AC Controllers)

- AC Motor Controllers/Display Panel D

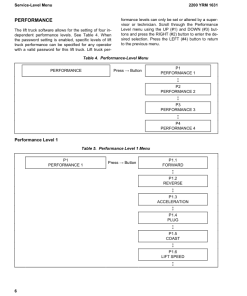

- Troubleshooting and Adjustments Using the AC Controls Program (ETACC)

- Electrical Diagrams AC Motor Control System

- Periodic Maintenance

- AC Motor Repair

- Capacities and Specifications

- Cylinder Repair

Only logged in customers who have purchased this product may leave a review.

Reviews

There are no reviews yet.